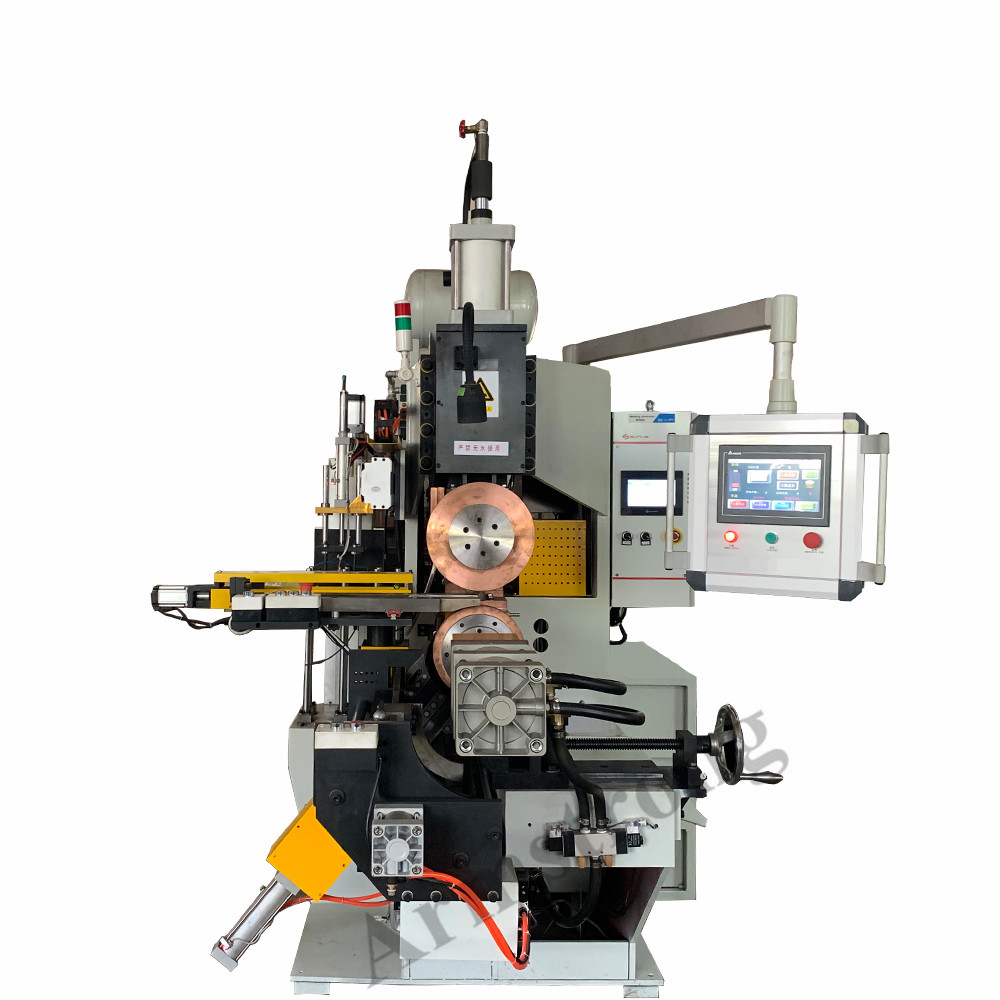

Roller Welding Machine A-BP400

Isicelo:

I-roller welding, eyaziwa nangokuthi i-circumferential seam welding, iyindlela esebenzisa ipheya lama-electrode e-roller esikhundleni sama-electrode angamacylindrical we-spot welding, futhi izinto zokusebenza ezishiselwe zihamba phakathi kwamarola ukuze kukhiqizwe i-weld evalayo enamanugi agqagqene ukushisela izinto zokusebenza.I-AC pulse current noma i-amplitude modulation current ivame ukusetshenziswa, futhi isigaba sesithathu (esisodwa) esilungisiwe, imvamisa emaphakathi kanye ne-high frequency DC yamanje nayo ingasetshenziswa.I-Roll welding isetshenziselwa kakhulu ukushisela ipuleti elincane leziqukathi ezivaliwe ezigubhu zikawoyela, amathini, ama-radiator, izindiza kanye namathangi kaphethiloli emoto, amarokhethi nemicibisholo.Ngokuvamile, ukushuba kokushisela kungaphakathi kwe-3mm yepuleti elilodwa.

Isicathulo sebhuleki emotweni ikakhulukazi sakhiwe ipuleti nombambo.Ngokuvamile sihlanganisa lezi zingxenye ezimbili ngenqubo yokushisela, kanye nemiphumela yomshini we-roller welding ngalesi sikhathi.Lo mshini wokushisela i-frequency roller welding yesicathulo se-automobile brake uyisisetshenziswa esikhethekile sokushisela esakhiwe futhi sakhiwe yinkampani yethu ukukhiqizwa kwamabhuleki ezimoto ngokuya ngezidingo zobuchwepheshe zokushisela izicathulo zamabhuleki.

Imishini inezinhlobonhlobo zezicelo futhi ifanele ukushiselwa kokuqiniswa okukodwa kwesicathulo se-automobile brake.Okokufaka kwedijithali kwesikrini sokuthinta kusetshenziselwa ukulawula izilungiselelo zokusebenza, okulula futhi okulula ukuzisebenzisa.

Izesekeli zemishini (i-panel material rack, box conductive, servo drive, clamping mold, pressure welding cylinder) yimikhiqizo edumile emhlabeni wonke.Ngaphezu kwalokho, isinciphisi seplanethi esinembayo esiphezulu singathuthukisa ukunemba kokuma kwesicathulo.

Iphinde yamukele i-microcomputer ye-chip eyodwa njengeyunithi yokulawula eyinhloko, enezici zesekethe elula, ukuhlanganiswa okuphezulu nobuhlakani, inciphisa izinga lokuhluleka futhi ilungele ukulungiswa.

Isigaba somsebenzi wokuxhumana nokulawula ikhodi ye-BCD ixhunywe ngaphandle nekhompyutha yezimboni, i-PLC nezinye izinto zokulawula ukuze kuqashwe isilawuli kude nokuphathwa okuzenzakalelayo, okuthuthukisa ukusebenza kahle komsebenzi.16 imininingwane yokushisela ingagcinwa ukuze abasebenzisi bashayele indawo yangaphambili.

Imvamisa yokuphuma kwesilawuli sefrikhwensi ephakathi yi-1kHz, futhi umthethonqubo wamanje uyashesha futhi unembile, ongenakufezwa ngemishini evamile yokushisela imvamisa yamandla.