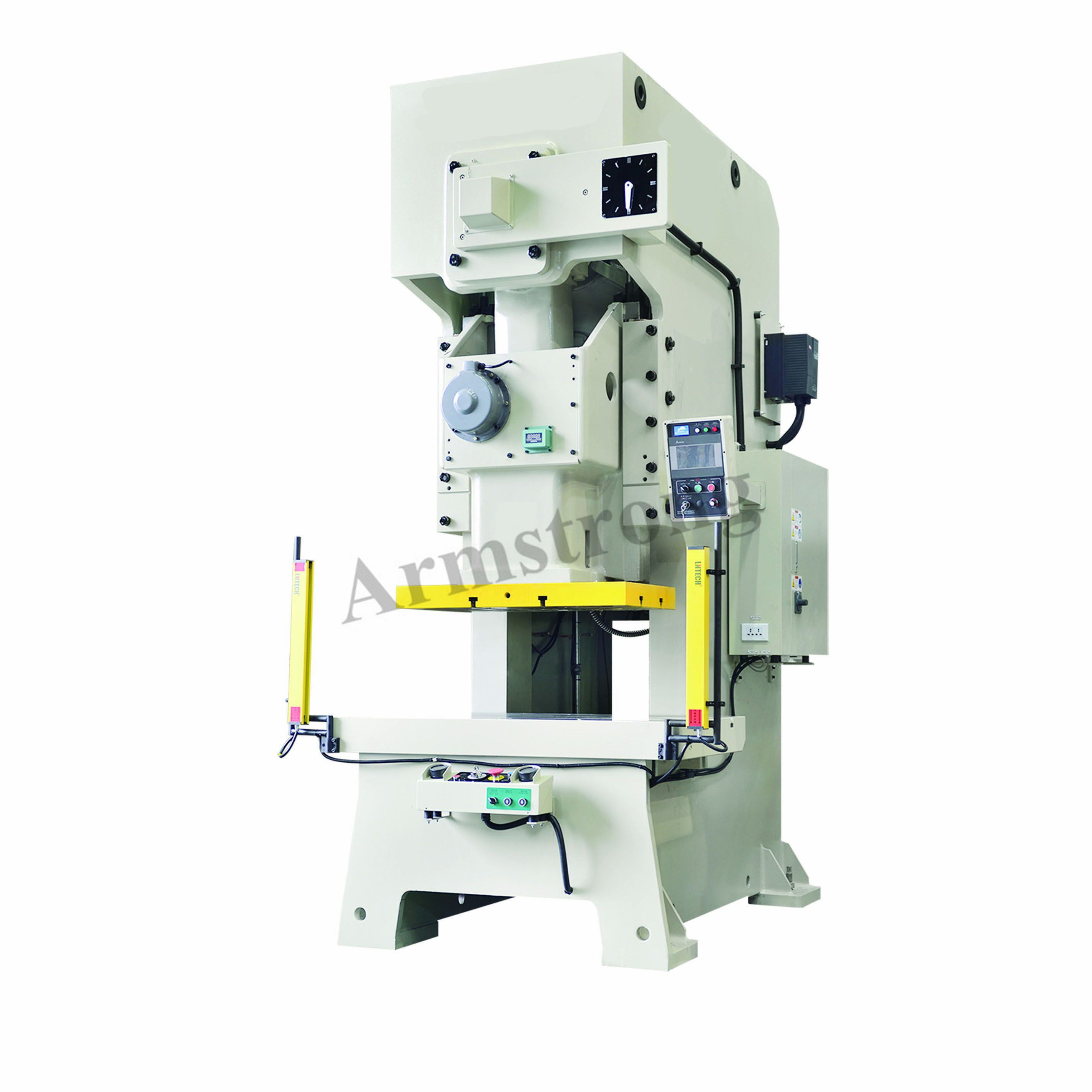

A-PM series Punching machine

I-Precision high-speed puncher yi-punch yokulawula idijithali ehamba phambili kunye nechanekileyo, eneempawu zokuchaneka okuphezulu, ukuqina, ukusebenza kakuhle kunye nokusebenza okulula.Ngethuba lokusebenza, umatshini olawulwa yikhompyutheni uguqula ukunyakaza kwesetyhula kwi-linear motion, kwaye ifake uxinzelelo kwizinto eziphathekayo ngokusebenzisa uchungechunge lwemisebenzi yokwenza i-deformation yeplastiki, ukuze ufumane ubume obufunekayo kunye nokuchaneka.

Isixhobo sinokusetyenziswa ngokubanzi kwi-stamping processing yamacandelo amancinci achanekileyo afana nokubethelwa kwepleyiti yangasemva.Ayinakugqobhoza kuphela ipleyiti engasemva erhabaxa kwipleyiti yentsimbi, kodwa iphinde icinezele izikhonkwane kwipleyiti yangasemva.Ngobungakanani beplate yangasemva kunye nobukhulu, siyile iimodeli ezahlukeneyo zepuncher zoxinzelelo olwahlukeneyo.Ngale ndlela, inokubethelela ipleyiti yangasemva yesithuthuthu, imoto yabakhweli kunye nezithuthi zorhwebo.

Izinto zethu eziluncedo:

1. Esi sixhobo sinokucinezela ngokuqhubekayo isitya sensimbi, esinokusebenza okuphezulu.Ukuba uxhotyiswe ngesixhobo sokutyisa esizenzekelayo, unokunyusa kakhulu umthamo wemveliso.

2. Zonke iidiski zolu chungechunge lwe-puncher zixhotyiswe nge-clutches ye-brake eyomileyo, kunye ne-valve ebukhali ye-solenoid ephindwe kabini (Yenziwe kwi-brand yaseJapan TACO) inokunciphisa ixesha lokuqhawula ngaphakathi komda.Ukongezelela, kwimeko yongxamiseko, isixhobo sesibini sokuhlalisa isistim sokuncedisa i-brake siza kubonelela ngesignali ye-brake kwakhona ukubonelela ngesignali ye-brake kwakhona ukunika amandla okwaneleyo ukuqinisekisa ukunyanzeliswa kwexesha kunye ngokuchanekileyo.

3. Sikwanika ingqalelo kukhuseleko lwabasebenzisi.Ngexesha loyilo, injineli yashiya indawo eyaneleyo phakathi kwamaqhosha amabini okusebenza kwezandla zomenzi we-gantry punch kunye nomzimba womatshini ukukhusela ukhuseleko lwezandla.Kwangaxeshanye, kwakuchaziwe kuyilo lwenkqubo ukuba ukusebenza kwezandla ezibini kuphela ngaxeshanye kunokuqalisa umatshini, ukuze kuthintelwe ukwenzakala komntu okubangelwa kukungasebenzi kakuhle.Ukufakwa kwezixhobo zokukhusela iifoto zombane okanye iinethi zokukhusela ziphucula ngakumbi ukukhuselwa kwabasebenzisi.

4. Ukhuseleko lokufa: Zonke iipunchers zixhotyiswe ngezixhobo ezigqithisiweyo zokukhusela i-dies from deformation kunye nomonakalo obangelwa ku-stamping overload.Isixhobo sokubona unikezelo olungalunganga lukwafakelwa ukusebenzisana nesixhobo sokufa sokucofa ngokuzenzekela ukukhusela ngcono ukufa.

Iiparamitha zobugcisa ezingaphelelanga:

| A-PM110 | |

| Inkcazo | I-CRANK PRESS ENYE |

| Umthamo woxinzelelo | 110 iitoni |

| Ilinganiswe ngeTonnage Point | 6 mm |

| Ukubetha ngomzuzu | 30-60 SPM |

| Ubude bestroke | 180 mm |

| Ukuphakama kokufa okuphezulu | 360 mm |

| Uhlengahlengiso lwesilayidi | 80mm |

| Min vala ubude bokufa | 280 mm |

| Ipleyiti yesilayidi(L*W*T) | 910*470*80 mm |

| Ipleyiti yeBolster(L*W*T) | 1150*600*110 mm |

| Die Shank Hole Dia | Φ50 mm |

| Injini engundoqo | 11 kW *4 |

| Uxinzelelo lomoya | 6kg/cm2 |

| Ubungakanani bePuncher (L*W*T) | 1900*1300*3200 mm |

| Ubunzima | 9.6 Iitoni |

| A-PM160 | |

| Inkcazo | I-CRANK PRESS ENYE |

| Umthamo woxinzelelo | 160 iitoni |

| Ilinganiswe ngeTonnage Point | 6 mm |

| Ukubetha ngomzuzu | 20-50 SPM |

| Ubude bestroke | 200 mm |

| Ukuphakama kokufa okuphezulu | 460 mm |

| Uhlengahlengiso lwesilayidi | 100mm |

| Ipleyiti yesilayidi(L*W*T) | 700*550*90 mm |

| Ipleyiti yeBolster(L*W*T) | 1250*800*140 mm |

| Die Shank Hole Dia | Φ65 mm |

| Injini engundoqo | 15 kW *4 |

| Uxinzelelo lomoya | 6kg/cm2 |

| Ubungakanani bePuncher (L*W*T) | 2300*1400*3800 mm |

| Ubunzima | Iitoni ezili-16 |