Umshicileli oshushu lelona nyathelo libalulekileyo neliyimfuneko kuzo zombini i-brake pad kunye ne-brake shoe friction linear production.Uxinzelelo, ubushushu bobushushu kunye nexesha lokukhupha zonke ziya kuchaphazela ukusebenza kwe-brake pad.Phambi kokuthenga umatshini wokushicilela oshushu olungele imveliso yethu, kufuneka siqale siwuqonde ngokupheleleyo umatshini wokushicilela oshushu.

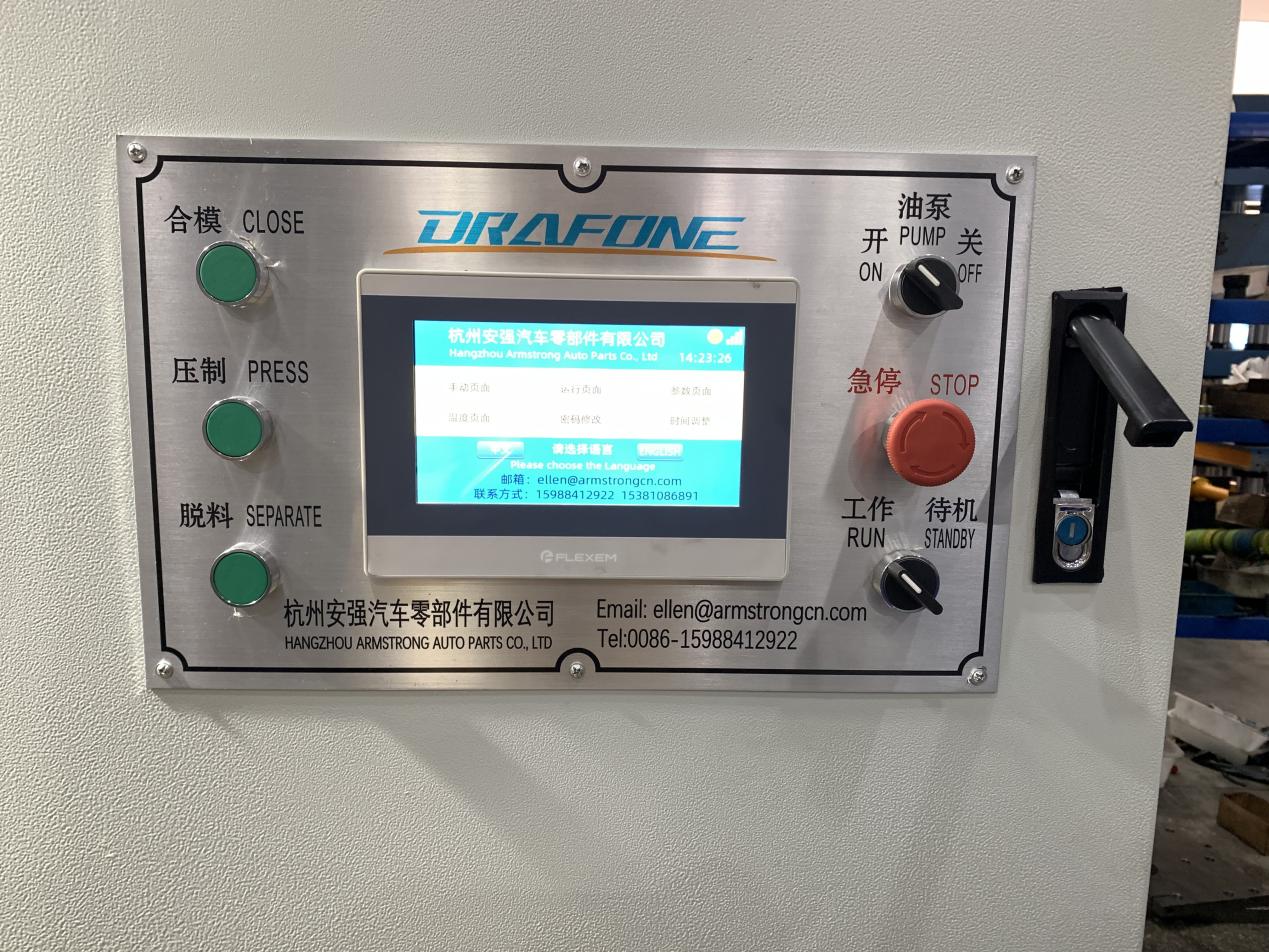

(Iiparamitha zilungiswe ngesikrini esichukumisayo)

Ukuphosa umshicileli oshushu kunye ne-welding press eshushu ziinkqubo ezimbini ezahlukileyo ngokupheleleyo kwimveliso yoshicilelo olushushu, ezinomahluko omkhulu kumgaqo, ukusetyenziswa, kunye nokusebenza.

Ukuphosa umatshini wokushicilela oshushu yinkqubo yokuvelisa ebandakanya ukunyibilikisa isinyithi kumaqondo obushushu aphezulu kunye noxinzelelo, kunye nokutofa kwimold ukwenza ubume obufunwayo.Isebenzisa amandla obushushu kunye noxinzelelo ukuguqula kunye nokuqinisa imathiriyeli.Ngaloo ndlela ukwenza i-cylinder engundoqo, ibhloko yesilayidi kunye nesiseko esisezantsi.Ngethuba lenkqubo, kufuneka kulungiswe isikhunta, ukutshisa izinto, ukulawula ukushisa kunye noxinzelelo, kunye nezinye iiparitha, emva koko ujobe izinto kwi-mold kwaye ulinde ukuba izinto ziqiniswe ngaphambi kokususa iindawo.

Kodwa kumatshini wokushicilela oshushu, inkqubo yokuvelisa yahluke ngokupheleleyo:

1) I-cylinder engundoqo, yenziwe ngentsimbi ejikelezayo esemgangathweni ophezulu ngokubumba (ukuphucula isakhiwo sangaphakathi sombutho wezinto eziphathekayo kunye nokwandisa amandla) - emva koko sebenzisa umatshini wokusika we-laser ukumba umngxuma ongaphakathi - ukuwelda nge-Q235 yentsimbi ephezulu. - ukucinywa ngokubanzi kunye nonyango lokunciphisa (ukuphelisa uxinzelelo lwangaphakathi) - ukulungiswa kakuhle.

I-2) Kwibhloko ye-sliding kunye nesiseko esisezantsi: sebenzisa i-Q235 ephezulu yensimbi ye-welding (umshini we-welding plate, amandla I-Factor of security ingaphezu kwamaxesha e-2) - ukucinywa kunye nokunyangwa kokunyangwa (ukupheliswa koxinzelelo lwangaphakathi) - ukulungiswa kakuhle.

Ngamafutshane, i-casting kunye ne-welding press ziindlela ezahlukeneyo zokuvelisa eziphuhliswe ngokusekelwe kwiimfuno ezahlukeneyo zokuvelisa kunye nemigaqo yenkqubo, efanelekileyo kwizinto ezahlukeneyo kunye neentlobo zemveliso.Ukukhetha kunye nokudibanisa ezi nkqubo ngokuchanekileyo kunokuhlangabezana ngcono neemfuno zeenkqubo ezahlukeneyo zemveliso.Kodwa ngokucinezela izinto ezikrwada, esekwe kumashumi eminyaka yamava emveliso, sicebisa ngakumbi oomatshini bokushicilela abashushu:

1. Isakhiwo sangaphakathi sokuphosa sikhululekile, sinamandla aphantsi, kwaye asikwazi ukumelana noxinzelelo oluphezulu.Amacandelo e-welding anamandla aphezulu, ukunyuka kwezinto zokhuseleko kwaye anokumelana noxinzelelo olukhulu.Emva kokubumba, iinxalenye ze-welding ziqinile ngaphakathi kwaye aziyi kuvelisa i-pinholes okanye i-cracks.

2. Amalungu angaphakathi e-castings athambekele ekuveliseni i-pores okanye i-pinholes, enokuthi ivuze ngokuthe ngcembe ngexesha lokusetyenziswa.

Ekubeni ukuveliswa kwee-brake pads kufuna iqondo elithile lokuchaneka ekucinezeleni okushushu, ngoko ke ii-welding presses zinconywa ngakumbi.

Iingcebiso ezincinci:

Ukuze wenze iphedi yebrake nganye ifumane uxinzelelo olwaneleyo, kunye nemingxuma eninzi kunye nexabiso eliphantsi lokuvelisa iipake pads, ngokuqhelekileyo iipakethi zeebhuleki ezahlukeneyo zisebenzisa ushicilelo olwahlukileyo kwiiToni:

Isithuthuthu iziqhoboshi pads- 200/300 Ton

Iiphedi zokuqhobosha zabakhweli- 300/400 Ton

Iipakethi zeebhuleki zemoto yorhwebo -400 Ton

(Hot press mold)

Ixesha lokuposa: Jun-26-2023