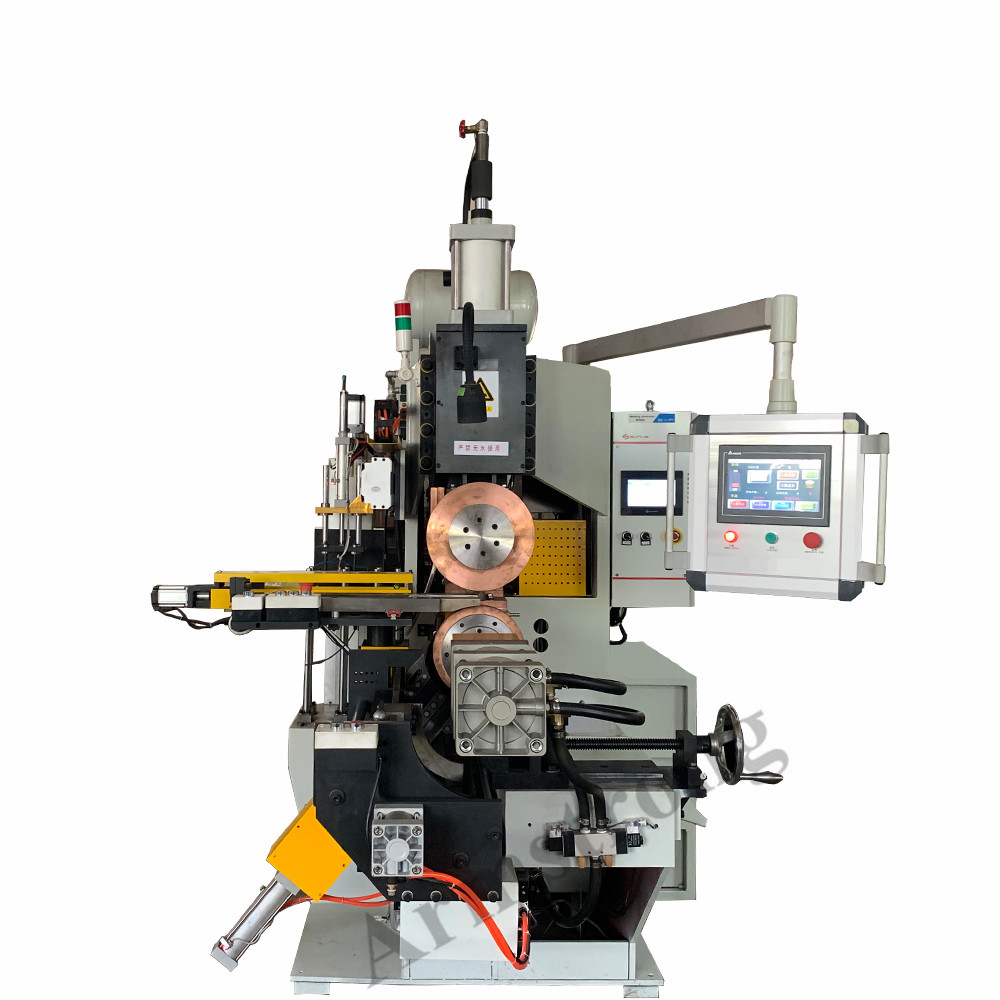

Roller Welding Machine A-BP400

Isicelo:

I-roller welding, ekwabizwa ngokuba yi-circumferential seam welding, yindlela esebenzisa iperi ye-electrode eqengqelekayo ukuze ithathe indawo ye-electrode yecylindrical ye-welding spot, kunye neendawo zokusebenza ezidityanisiweyo zihamba phakathi kweerola ukuvelisa i-weld yokutywina enama-nuggets adlulanayo ukuze weld workpieces.I-AC pulse current okanye i-amplitude modulation current isetyenziswa ngokubanzi, kwaye ezintathu (esinye) isigaba esilungisiweyo, i-intermediate frequency kunye ne-high frequency ye-DC yangoku nayo ingasetyenziswa.Ukuwelda kusetyenziselwa kakhulu ukuwelda ipleyiti encinci yezikhongozeli ezitywiniweyo kwimigqomo yeoli, iitoti, iiradiyetha, iinqwelomoya kunye neetanki zamafutha emoto, iirokethi kunye nemijukujelwa.Ngokuqhelekileyo, ubukhulu be-welding bungaphakathi kwe-3mm yepleyiti enye.

Isihlangu sebrake kwinqwelo-mafutha ubukhulu becala senziwe ngepleyiti kunye nombambo.Ngokuqhelekileyo sidibanisa ezi nxalenye zimbini ngenkqubo ye-welding, kunye ne-roller welding machine effects ngeli xesha.Lo matshini wokuwelda we-roller ophakathi wesihlangu se-auto brake sisixhobo sokuwelda esikhethekileyo esiyilwe kwaye senziwa yinkampani yethu ukuvelisa i-auto brake ngokweemfuno zobugcisa be-welding yezihlangu ze-brake.

Isixhobo sinoluhlu olubanzi lwezicelo kwaye lufanelekile kwi-welding yokuqiniswa okukodwa kwe-automobile brake shoe.Igalelo ledijithali lesikrini sokuchukumisa lisetyenziselwa ukulawula useto lokusebenza, olulula kwaye lulungele ukusebenza.

Izixhobo zezixhobo (i-panel material rack, ibhokisi ye-conductive, i-servo drive, i-clamping mold, i-cylinder welding welding) ziimveliso ze-brand eyaziwayo kwihlabathi.Ukongezelela, i-high-precision reducer yeplanethi inokuphucula ukuchaneka kokumisa isihlangu.

Kwakhona yamkela i-microcomputer ye-chip enye njengeyunithi yokulawula eyintloko, eneempawu zesekethe elula, ukudibanisa okuphezulu kunye nobukrelekrele, ukunciphisa izinga lokungaphumeleli kwaye kulungele ukugcinwa.

Unxibelelwano kunye necandelo lomsebenzi wekhowudi yokulawula ikhowudi ye-BCD ixhunywe ngaphandle kunye nekhompyutheni yezoshishino, i-PLC kunye nezinye izixhobo zokulawula ukuqaphela ukulawulwa kude kunye nokulawulwa ngokuzenzekelayo, okuphucula ukusebenza kakuhle.16 iinkcukacha ze-welding zinokugcinwa ukuze abasebenzisi babize i-preposition.

Isiphumo sokuphuma kwesilawuli sefrikhwensi ephakathi yi-1kHz, kwaye ummiselo wangoku ukhawuleza kwaye uchanekile, ongenako ukufezekiswa ngoomatshini abaqhelekileyo bombane we-welding.