Hot press is the most important and necessary step in both brake pad and brake shoe friction linear production. The pressure, heat temperature and exhaust time will all affect brake pad performance. Before buying a hot press machine which suitable for our own products, we must first have a full understanding of the hot press machine.

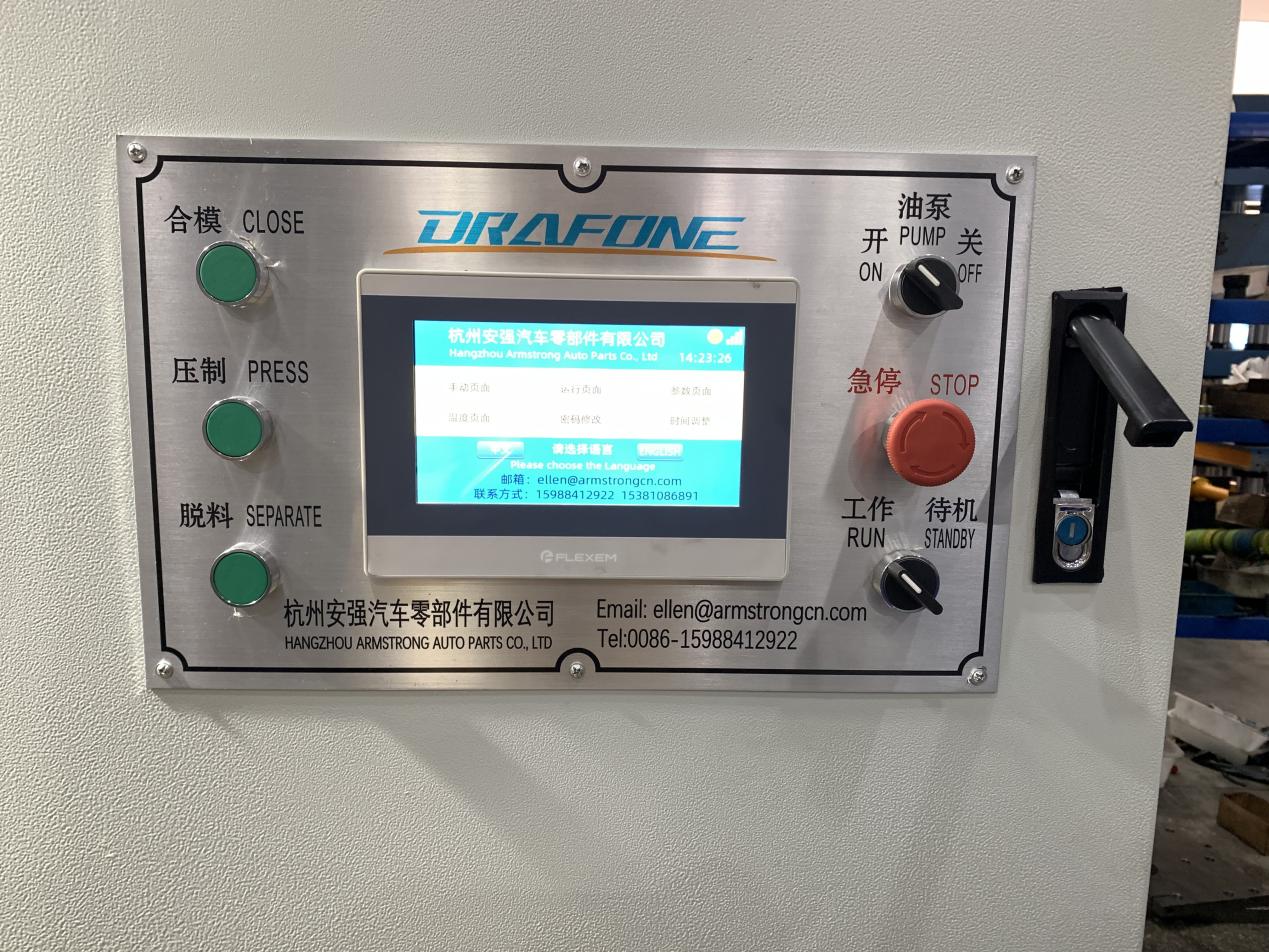

(Parameters settled by touch screen)

Casting hot press and welding hot press are two completely different manufacturing processes in hot press production, which have significant differences in principle, application, and operation.

Casting hot press machine is a manufacturing process that involves melting metal at high temperatures and pressures, and injecting them into a mold to form the desired shape. It utilizes heat energy and pressure to deform and solidify materials. Thus to make main cylinder, sliding block and bottom base. During the process, it needs to prepare the mold, preheat the material, control temperature and pressure, and other parameters, then inject the material into the mold and wait for the material to solidify before removing the parts.

But for welding hot press machine, the manufacturing process is totally different:

1)For main cylinder, it is made of high-quality solid round steel through forging (improving the internal organizational structure of the material and increasing strength) – then use laser cutting machine to excavate the inner cavity – welding with Q235 high-quality steel – overall quenching and tempering treatment (eliminating internal stress) – fine processing.

2)For sliding block and bottom base: use Q235 high-quality steel for welding (thick plate welding machine, strength Factor of safety is more than 2 times) – quenching and tempering treatment (elimination of internal stress) – fine processing.

In short, casting and welding press are different manufacturing methods developed based on different manufacturing needs and process principles, suitable for different materials and product types. Choosing and combining these processes correctly can better meet the needs of different production processes. But for raw material pressing, based on decades of production experience, we more recommend the welding hot press machines:

1. The internal structure of the casting is relatively loose, with low strength, and cannot withstand high pressure. The welding parts has high strength, increased factor of safety and can withstand greater pressure. After forging, the welding parts are tight inside and will not produce pinholes or cracks.

2. The internal parts of castings are prone to producing pores or pinholes, which may gradually leak during use.

Since the production of brake pads requires a certain degree of precision in hot pressing, so welding presses are still more recommended.

Small Tips:

In order to make each brake pad get enough pressure, and with much cavities and low cost to produce brake pads, usually different brake pads use different press in Tons:

Motorcycle brake pads- 200/300 Ton

Passenger brake pads- 300/400 Ton

Commercial vehicle brake pads -400 Ton

(Hot press mold)

Post time: Jun-26-2023