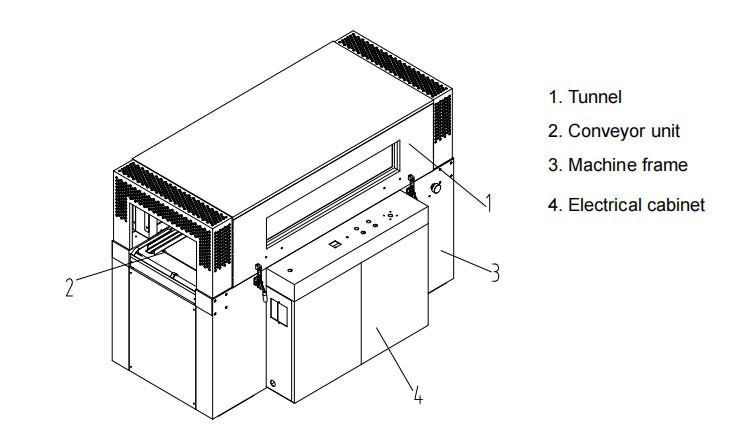

Heat Shrink Machine

Main components of the machine

Advantage:

The advantages of heat shrink packaging machines are mainly reflected in:

Cost effectiveness:

Compared with other packaging methods, heat shrink packaging has lower costs and can effectively extend the shelf life of products.

Flexibility:

Suitable for products of various shapes and sizes, with high adaptability.

Enhance product appearance:

Heat shrink packaging can make products look neater and more upscale, which helps to enhance brand image.

Easy operation:

The wind direction, wind speed and wind force of the whole machine are adjustable, the furnace cover can be opened freely, the heating body uses double-layer toughened glass, and the cavity can be seen.

|

Technical Specifications |

|

|

Power |

380V, 50Hz, 13kw |

|

Overall dimensions(L*W*H) |

1800*985*1320 mm |

|

Heating cavity dimensions(L*W*H) |

1500*450*250 mm |

|

Worktable height |

850 mm (adjustable) |

|

Conveying speed |

0-18 m/min (adjustable) |

|

Temperature range |

0~180℃ (adjustable) |

|

Using temperature range |

150-230℃ |

|

Main material |

Cold plate, Q235-A steel |

|

Applicable shrink film |

PE, POF |

|

Applicable film thickness |

0.04-0.08 mm |

|

Heating pipe |

Stainless steel heating tube |

|

Conveying belt |

08B hollow chain rod conveying, covered with high temperature resistant silicone hose |

| Machine performance |

Frequency control, automatic temperature regulation, solid-state relay control. It’s stable and reliable, with long service life and low noise. |

| Electrical configuration |

Centrifugal fan; 50A switch (Wusi); Frequency converter: Schneider; Temperature control instrument, small relay and thermocouple: GB, Motor: JSCC |

Video