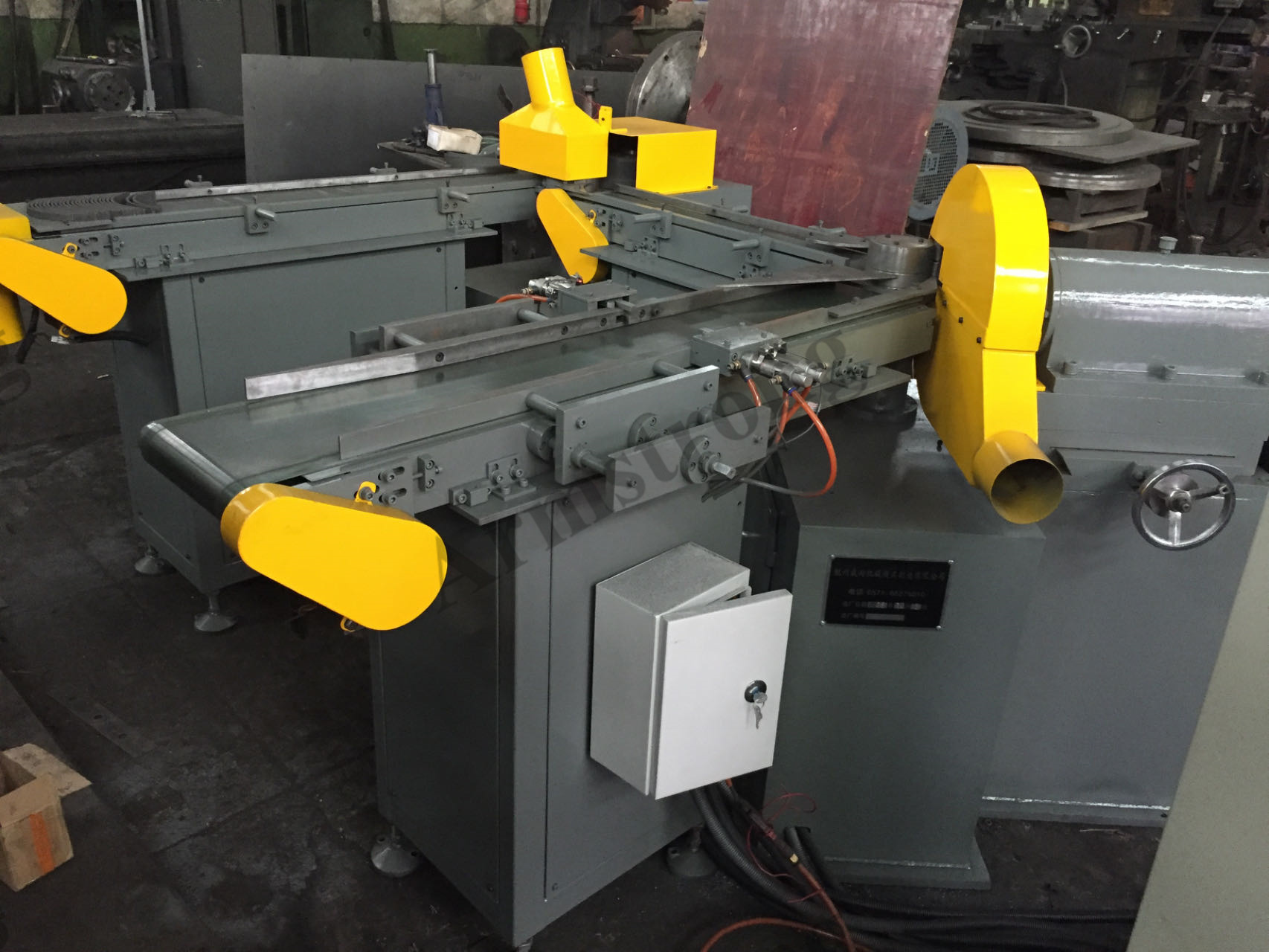

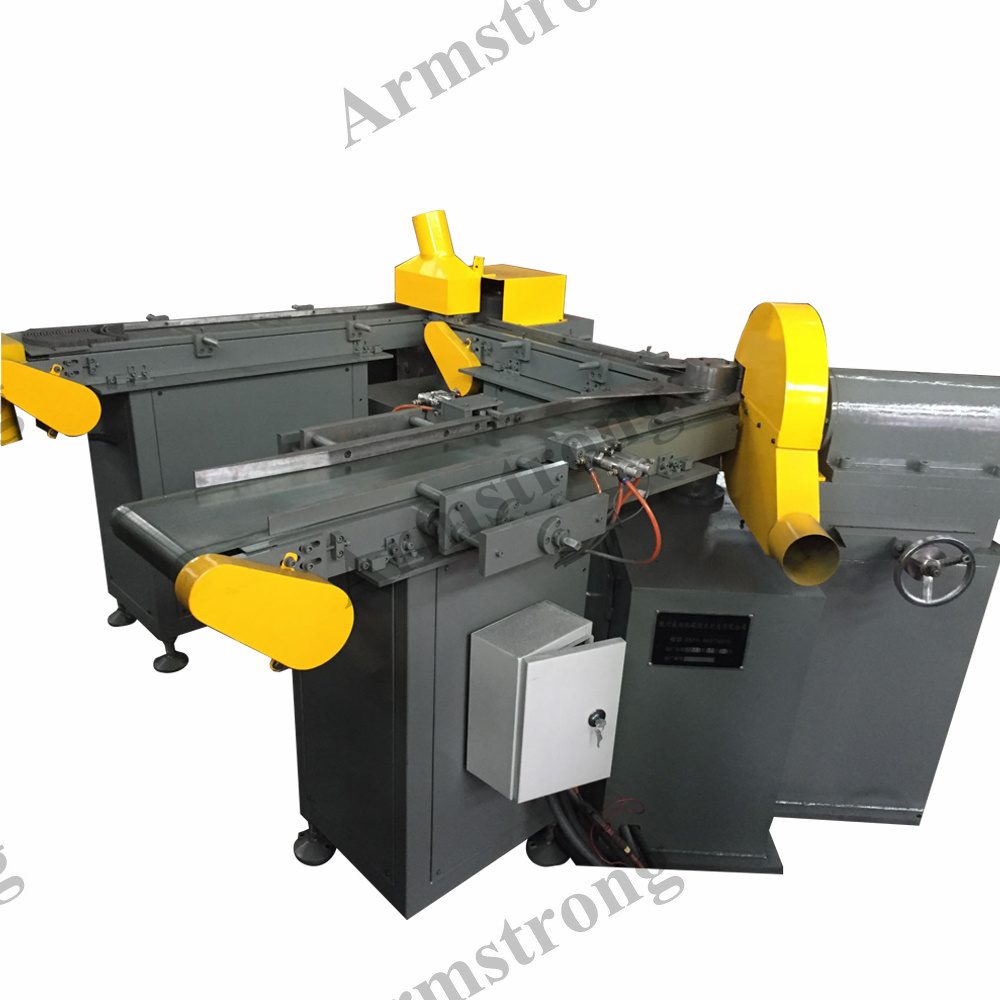

Inner & outer combined grinding machine

Application:

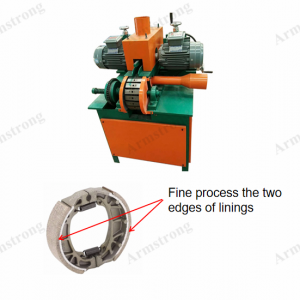

To grind the inner arc and outer arc of brake shoe linings (liner).

After the brake shoe liner come out from the hot press machine, the liner arc cannot be 100% flat and size correct. Thus the inner arc grinding machine and outer arc grinding machine will be applied after pressing, to make sure the liner arc can match the brake shoe metal parts well.

Inner & outer arc grinding machine is a breakthrough innovation for this two grinding process. It combines inner arc grinding and outer arc grinding together, reduce the labor request and become more automatically.

Advantages:

High Efficiency: The combined grinder can perform multiple processing operations on a single equipment (inner & outer arc), improving production efficiency. In addition, the machine equips with auto feeding and stacking device. Worker just need to place the shoe liners on feeding area, the machine will auto feed the liners into grinding stations, and auto stacking it when both stations finish grinding. One worker can operate 3-4 sets at same time, save the labor cost.

Space saving: Compared to individual grinding machine, combined grinding machines occupy less space, which helps optimize workshop layout.

Flexibility: Combination grinders are designed with adjustable versatility, suitable for different brake shoe grinding needs, and improving production flexibility.

High Precision: The grinders adopts high accuracy grinding wheel, which can keep the grinding parallel thickness error less than 0.1 mm. It has high machining accuracy and can meet the requirements of OEM shoe lining production request.