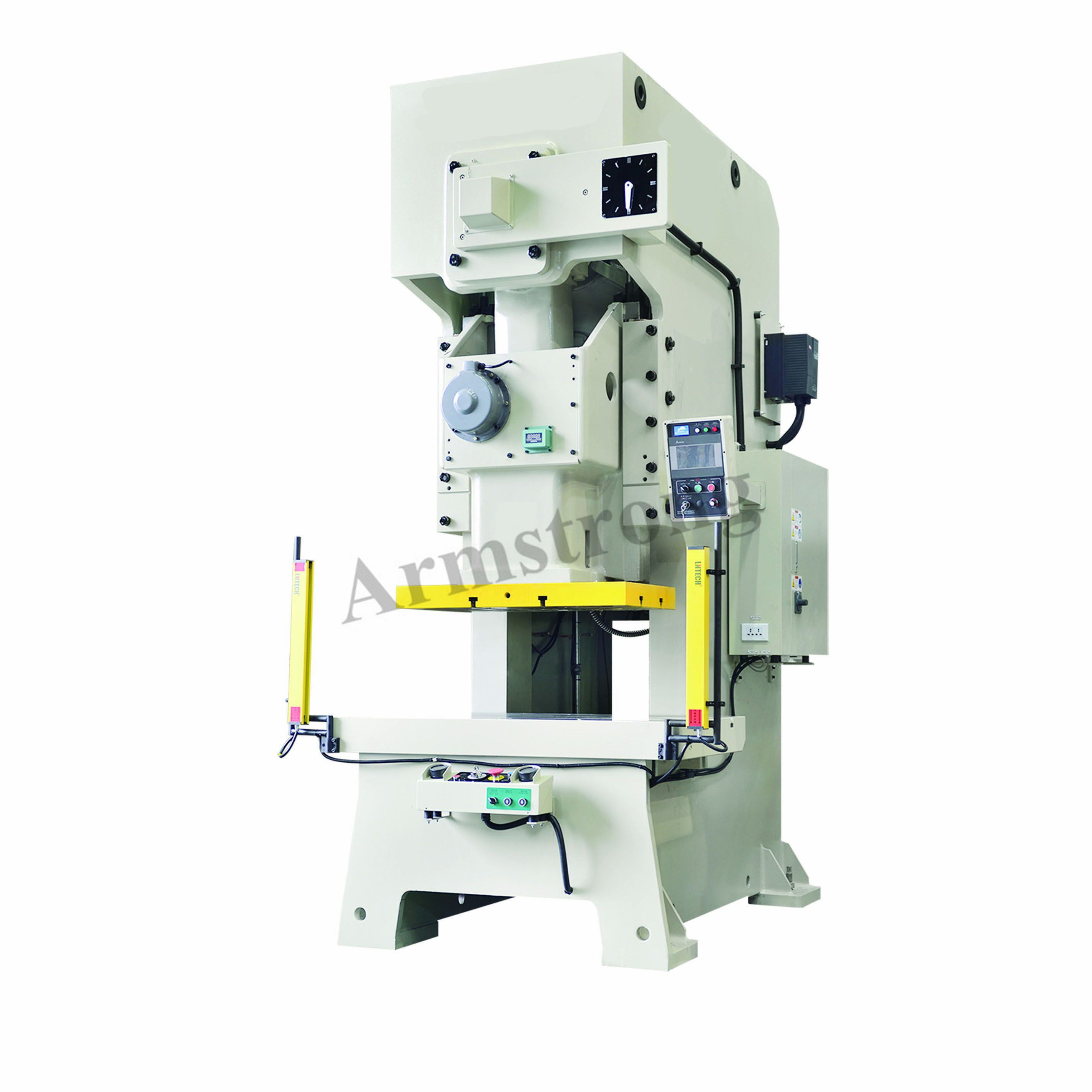

A-PM letoto la ho phunya mochini

Precision high-speed puncher ke lebelo le phahameng le le nepahetseng la taolo ea dijithale, e nang le litšoaneleho tsa ho nepahala ho phahameng, ho tiea, ho sebetsa hantle le ts'ebetso e bonolo.Nakong ea ts'ebetso, mochine o laoloang ke k'homphieutha o fetola ho sisinyeha ha selikalikoe hore e be motsamao oa mola, 'me o sebelisa khatello ho thepa ka letoto la mosebetsi oa ho e etsa deformation ea polasetiki, e le ho fumana sebopeho se hlokahalang le ho nepahala.

Thepa e ka sebelisoa haholo ha ho etsoa litempe tsa likarolo tse nyane tse nepahetseng joalo ka ho phunya poleiti ka morao.Ha e khone feela ho phunya poleiti e ka morao e makukuno holim'a poleiti ea tšepe, empa hape e hatella lithakhisa ka mokokotlong.Bakeng sa boholo bo fapaneng ba poleiti ea ka morao le botenya, re entse mefuta e fapaneng ea li-puncher tsa likhatello tse fapaneng.Ka tsela ena, e ka phunya poleiti e ka morao bakeng sa sethuthuthu, koloi ea baeti le likoloi tsa khoebo.

Melemo ea rona:

1. Thepa ena e ka tsoela pele ho hatella tšepe ea tšepe, e nang le bokhoni bo phahameng.Haeba e hlomelloa ka sesebelisoa sa ho fepa ka boiketsetso, e ka eketsa matla a tlhahiso haholo.

2. Li-discs tsohle tsa letoto lena la puncher li na le li-clutch tse tsoetseng pele tse omeletseng, 'me valve e bohale ea solenoid (E entsoeng ka TACO ea Japane) e ka khutsufatsa nako ea braking ka har'a moeli.Ho phaella moo, ha ho e-na le ts'ohanyetso, sesebelisoa sa bobeli sa ho lulisa sa "brake assist" se tla fana ka lets'oao la brake hape ho fana ka lets'oao la brake hape ho fana ka matla a lekaneng ho netefatsa braking e nakong le e nepahetseng.

3. Hape re ela hloko polokeho ea basebelisi.Nakong ea moralo, moenjiniere o ile a siea sebaka se lekaneng pakeng tsa likonopo tse peli tsa ts'ebetso ea matsoho tsa moetsi oa gantry punch le 'mele oa mochini ho sireletsa polokeho ea matsoho.Ka nako e ts'oanang, ho ile ha boleloa moralong oa tsamaiso hore ke matsoho a mabeli feela a ka qalang mochine ka nako e le 'ngoe, e le ho qoba kotsi ea botho e bakoang ke ho se sebetse hantle.Ho kenya lisebelisoa tsa ts'ireletso ea photoelectric kapa matlooa a sireletsang ho ntlafatsa ts'ireletso ea basebelisi.

4. Tšireletso ea lefu: Li-punchers tsohle tse nang le lisebelisoa tse ngata ho sireletsa li-dies from deformation le tšenyo e bakoang ke overload stamping.Ho boetse ho kentsoe sesebelisoa sa ho bona hore ha se tsamaee hantle ho sebelisana le sesebelisoa sa autostamping ho sireletsa lefu.

Likarolo tse itseng tsa tekheniki:

| A-PM110 | |

| Tlhaloso | MOTS'ELISI KHABELE |

| Bokhoni ba khatello | Lithane tse 110 |

| E lekantsoe Tonnage Point | 6 limilimithara |

| Stroke ka motsotso | 30-60 SPM |

| Bolelele ba stroke | 180 limilimithara |

| Max shut die height | 360 limilimithara |

| Phetoho ea li-slide | 80 limilimithara |

| Min shut die height | 280 limilimithara |

| Slide plate(L*W*T) | 910*470*80 limilimithara |

| Bolster plate(L*W*T) | 1150*600*110 limilimithara |

| Die Shank Hole Dia | Φ50 limilimithara |

| Enjene e ka sehloohong | 11kW *4 |

| Khatello ea moea | 6kg/cm2 |

| Puncher dimension(L*W*T) | 1900*1300*3200 limilimithara |

| Boima ba 'mele | 9.6 Lithane |

| A-PM160 | |

| Tlhaloso | MOTS'ELISI KHABELE |

| Bokhoni ba khatello | 160 Lithane |

| E lekantsoe Tonnage Point | 6 limilimithara |

| Stroke ka motsotso | 20-50 SPM |

| Bolelele ba stroke | 200 limilimithara |

| Max shut die height | 460 limilimithara |

| Phetoho ea li-slide | 100mm |

| Slide plate(L*W*T) | 700*550*90 limilimithara |

| Bolster plate(L*W*T) | 1250*800*140 limilimithara |

| Die Shank Hole Dia | Φ65 limilimithara |

| Enjene e ka sehloohong | 15kW *4 |

| Khatello ea moea | 6kg/cm2 |

| Puncher dimension(L*W*T) | 2300*1400*3800 limilimithara |

| Boima ba 'mele | Lithane tse 16 |