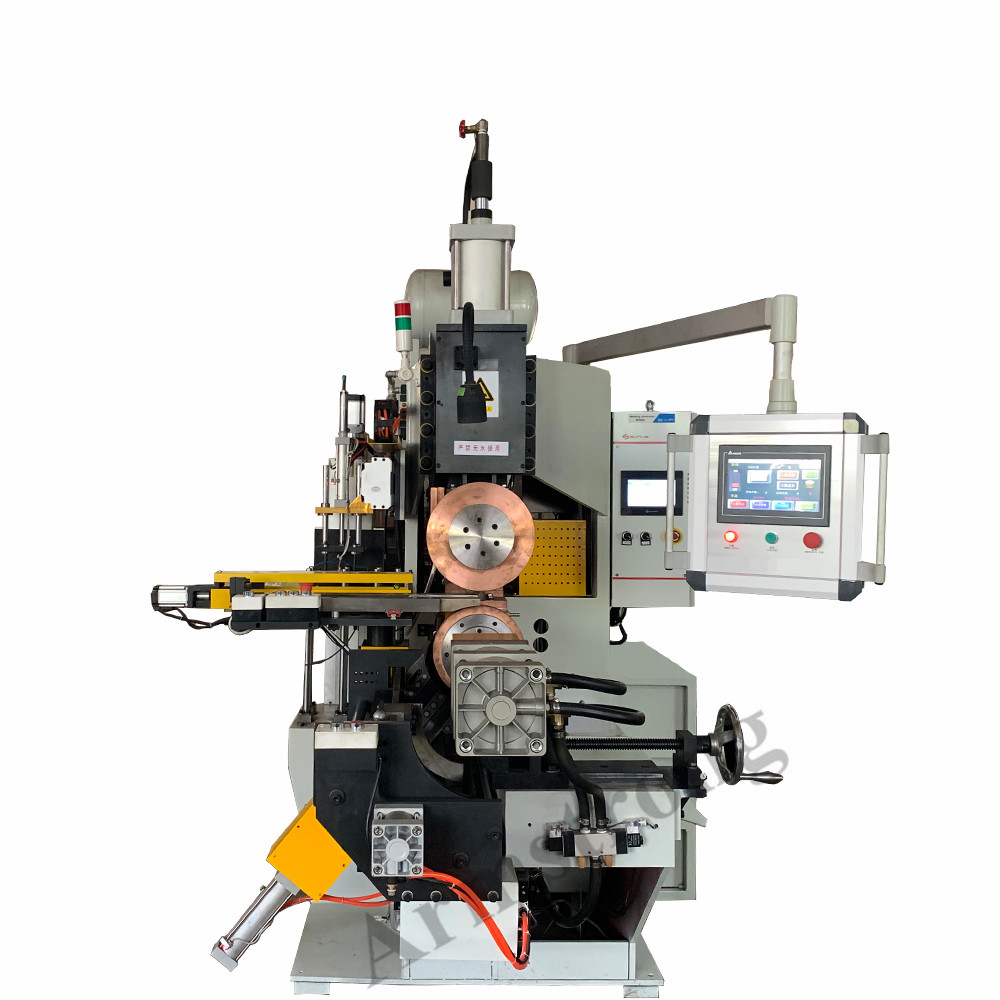

Roller Welding Machine A-BP400

Kopo:

Roller tjheseletsa, eo hape e tsejoang e le circumferential seam tjheseletsa, ke mokhoa o sebelisang para ea li-electrode rolara ho nka sebaka sa li-electrode cylindrical ea tjheseletsa letheba, 'me workpieces welded tsamaea pakeng tsa rollers ho hlahisa tiiso tjheseletsa ka nuggets overlapping ho weld workpieces.AC pulse current kapa amplitude modulation current e sebelisoa ka kakaretso, 'me ho ka sebelisoa mekhahlelo e meraro (e le 'ngoe) e lokisoang, maqhubu a mahareng le maqhubu a phahameng a DC le eona e ka sebelisoa.Roll welding e sebelisoa haholo bakeng sa tjheseletsa e tšesaane ea lijana tse tiisitsoeng ka har'a meqomo ea oli, makotikoti, li-radiator, lifofane le litanka tsa mafura a koloi, lirokete le limisaele.Ka kakaretso, botenya ba tjheseletsa bo kahara 3mm ea poleiti e le 'ngoe.

Brake shoe ka koloing e entsoe haholo ka poleiti le likhopo.Hangata re kopanya likarolo tsena tse peli ka mokhoa oa ho tjheseletsa, le liphello tsa mochine oa welding oa rolara ka nako ena.Mochini ona oa tjheseletsa oa maqhubu a mahareng bakeng sa brake shoe ea koloi ke sesebelisoa se khethehileng sa tjheseletsa se entsoeng le ho etsoa ke k'hamphani ea rona bakeng sa tlhahiso ea brake ea likoloi ho latela litlhoko tsa tekheniki tsa welding tsa lieta tsa brake.

Thepa e na le mefuta e mengata ea lits'ebetso 'me e loketse ho tjheseletsa ha reinforcement e le' ngoe ea brake shoe ea koloi.Kenyelletso ea dijithale ea skrineng sa touch e sebelisoa ho laola litlhophiso tsa ts'ebetso, tse bonolo ebile li bonolo ho sebetsa.

Lisebelisoa tsa lisebelisoa (rack material rack, conductive box, servo drive, clamping hlobo, pressure welding cylinder) ke lihlahisoa tse tsebahalang lefatšeng ka bophara.Ho phaella moo, ho fokotsa lipolanete tse phahameng ka ho fetisisa ho ka ntlafatsa boemo bo nepahetseng ba seeta.

E boetse e nka microcomputer e le 'ngoe e le sesebelisoa se ka sehloohong sa taolo, se nang le litšobotsi tsa potoloho e bonolo, kopanyo e phahameng le bohlale, e fokotsa sekhahla sa ho hloleha mme e loketse tlhokomelo.

Karolo ea ts'ebetso ea puisano le taolo ea khoutu ea BCD e hokahane ka ntle le komporo ea indasteri, PLC le lisebelisoa tse ling tsa taolo ho hlokomela taolo e hole le taolo ea othomathiki, e ntlafatsang katleho ea mosebetsi.Litlhaloso tsa welding tse 16 li ka bolokoa hore basebelisi ba letse boemo ba pele.

Maqhubu a sephetho sa taolo ea maqhubu a mahareng ke 1kHz, 'me molao oa hajoale o potlakile ebile o nepahetse, o ke keng oa finyelloa ka mechini e tloaelehileng ea tjheseletsa ea matla.