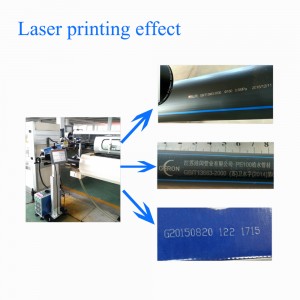

Laser Engraver fiber laser printing machine

Codsiga:

Aqoonsiga alaabta iyo raadinta: Mashiinka calaamadaynta laysarka ee khadka tooska ah wuxuu si toos ah u xarri karaa lambarka taxan ee alaabta, lambarka dufcada, taariikhda wax soo saarka iyo macluumaadka kale ee dusha alaabta, gaarista aqoonsiga badeecada iyo raadinta.Tani waxay muhiimad weyn u leedahay xakamaynta tayada, adeegga iibka kadib, iyo dabagalka alaabta.

Ka-hortagga been-abuurka iyo raad-raacista: Tignoolajiyada calaamadeynta laser-ka waxay gaari kartaa mid yar oo adag in lagu daydo calaamadaha alaabada, waxaana lagu dabaqi karaa dhinacyada ka-hortagga been-abuurka iyo raadinta.si loo hubiyo saxnimada iyo badbaadada suufka biriiga.

Calaamadaynta qaybaha: Mashiinnada calaamadaynta laser waxay calaamadin karaan qaybaha alaabta si sahlan oo loo maareeyo.

Faa'iidooyinka

Wax soo saar wax ku ool ah: Naqshadeynta khadka isku dhafka ah ayaa u sahlaysa mashiinka calaamadaynta laysarka in uu si aan kala go 'lahayn ugu xidho khadka wax soo saarka, gaarista calaamadaynta alaabta joogtada ah.Marka la barbar dhigo calaamadaynta buug-gacmeedka ama mashiinnada calaamadaynta si gaar ah u shaqeeya, waxay si weyn u wanaajin kartaa wax-soo-saarka waxayna si dhakhso ah u dhammaystiri kartaa hawlaha calaamadaynta.

Hawlgalka Automation-ka: Mashiinka calaamadaynta laydhka laysarka waxaa lagu dhex dari karaa qalabka otomaatiga ah si loo gaaro hawlgal toos ah oo toos ah, badbaadinta wakhtiga iyo kharashka shaqada ee hawlgalka gacanta.Shaqaaluhu waxa ay u baahan yihiin oo kaliya in ay alaabta dul dhigaan suunka wax qaada, dhammaan habka calaamadaynta waxa si toos ah u dhamaystiraya mishiinka.

Calaamadaynta saxda ah: Tignoolajiyada calaamadaynta laser waxay leedahay saxnaan iyo xasillooni aad u sareysa, taasoo gaari karta saameyn sax ah.Mashiinka calaamadaynta laydhka laydhka ayaa ku qalabaysan nidaamka xakamaynta xirfadlaha ah iyo madaxa laser, kaas oo si sax ah u xardhi kara qaababka calaamadaynta ama qoraalka alaabta, hubinta tayada calaamadaynta.

Debacsanaan sare: Mashiinka calaamadaynta laydhka laysarka ayaa la hagaajin karaa oo loo habeyn karaa iyadoo loo eegayo qaabka iyo cabbirka alaabta kala duwan.Ku qalabaysan hawlo ay ka mid yihiin hagaajinta dhererka, hagaajinta booska, iyo beddelka moduleka si uu ula qabsado meelaynta iyo calaamadaynta baahiyaha bireega kala duwan.