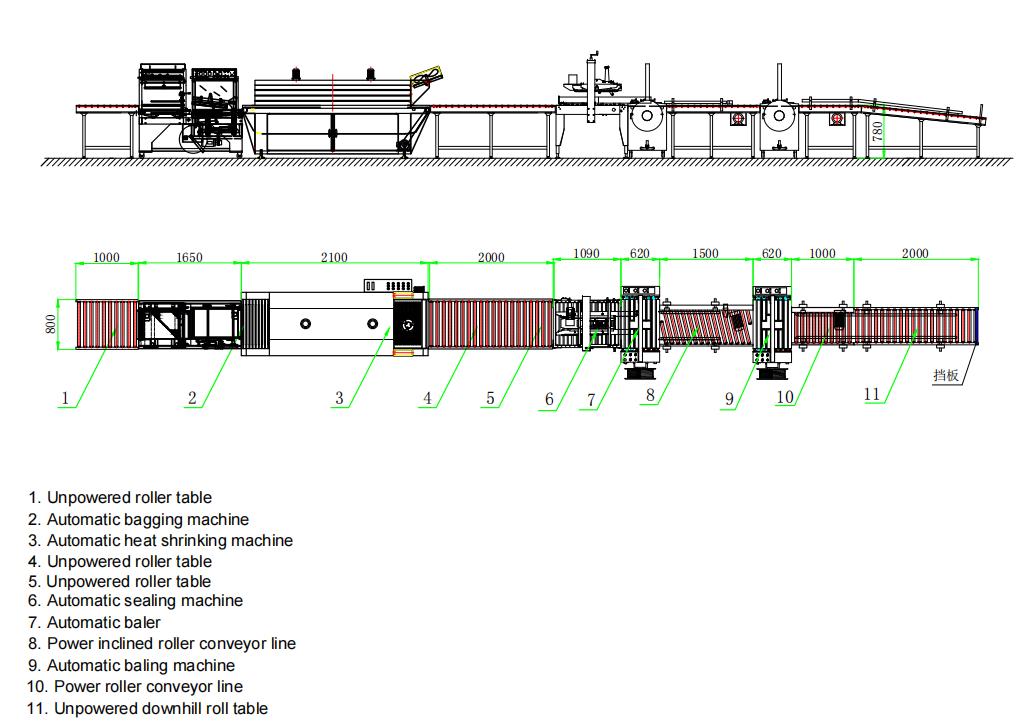

Shrink Wapper

Packaging flow

|

Specific working process |

|

|

1. |

Product input |

|

2. |

Bagging thermal shrinkage |

|

3. |

Manual packing |

|

4. |

Automatic sealing packaging |

|

5. |

Transfer |

|

6. |

Strapping packaging |

|

7. |

Product output |

|

Note: The line configuration is adjustable, design by the factory layout and detailed packaging request. |

|

Shrink wrapper machine, also known as bagging machine, is mainly used to wrap products with heat shrink film, and then heat the film with a heat shrink machine to shrink and tightly wrap the product. This type of machine is commonly used in industries such as food, medicine, and chemical engineering, which can improve the packaging efficiency and quality of products, as well as help extend the shelf life of products and enhance their appearance appeal. After the production of passenger car brake pads, they are usually packaged in sets of four pieces.

The working principle of the bagging machine includes the following steps:

1. Film feeding: The film enters the working area of the bagging machine through the feeding device.

2. Film opening: After the film enters the working area, the automatic bagging machine automatically opens the bag, making it appear in an open state.

3. Product loading: The product enters the film bag through the conveying belt, and the quantity of products in the bag can be adjusted as needed. The size of the bag can also be changed according to the size of the product.

4. Sealing: After the products in the bag are loaded, the automatic bagging machine will automatically seal the bag by high temperature cutter.

5. Discharge: After the bag is sealed, the automatic bagging machine will send the bag out and enter the heat shrink machine.

Compared to traditional manual bagging, automatic bagging machines have obvious advantages, such as fast speed, high efficiency, stable and reliable packaging quality, and can effectively ensure the quality and hygiene of goods.

|

Technical Specifications |

|

|

Power |

1P, AC220V, 50Hz, 3kw |

|

Compressed air pressure |

0.6-0.8 Mpa |

|

Worktable height |

780mm |

|

Bagging speed |

10-20 pcs/min |

|

Max edge banding size |

550*450 mm (L*W) |

|

Max package size |

L+H<500 mm, W+H<400 mm, H<150 mm |

|

Applicable film roll size |

Φ250* W550 mm |

|

Film material |

POF for PE film |

|

Overall dimensions(L*W*H) |

1670*780*1520 mm |

|

Electrical configuration |

Intermediate relay: Schneider Contactor: Schneider Buttons: Siemens APT Temperature Controller: GB/OMRON Time relay: GB Motor: JWD Pneumatic components: AirTAC |

|

Noise |

in working environment: ≤ 75dB (A) |

|

Environmental requirement |

Humidity ≤ 98%, Temperature: 0-40 ℃ |

Video