Shoe plate gluing line

Production detail

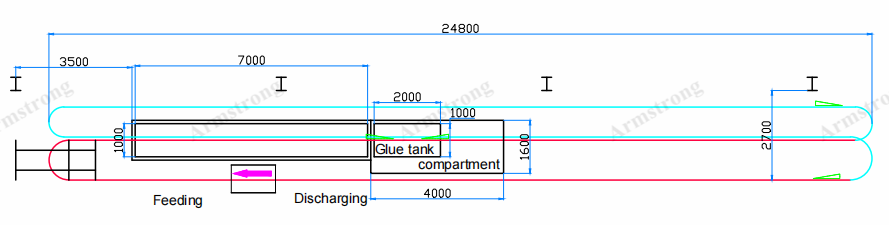

Gluing line drawing

The glue dipping requires hanging the shoe plate on the conveyor chain, so that the shoe plate can first pre heating and travel a certain distance in the glue solution in the dipping pool under the drive of the conveyor chain. After gluing, the shoe plate will be raised up to second floor and naturally dry out with long distance. Finally, the shoe plate is returned to the ground floor by conveyor and taken out.

Working flow:

|

No. |

Process |

TEMP |

Time (mins) |

Note |

|

1 |

Feeding |

|

|

Manual |

|

2 |

Pre heating |

50-60℃ |

4.5 |

|

|

3 |

Immerse in glue |

Room TEMP |

0.4 |

|

|

4 |

Leveling and air drying |

Room TEMP |

50 |

|

|

5 |

Discharge |

|

|

Manual |

Pls note: The line length and whole space arrangement can be designed according to customer factory.

2 floors design

Glue tank

Advantages:

1.The whole chain length is about 100m, assembled from straight and curved rails. The entire track also designed as a 2-floors structure to minimize footprint.

2.The tunnel temperature is automatically controlled by a digital temperature controller, which can display and control the tunnel temperature in real time.

3.All motors are protected against overload and short circuit.

4.Emergency stop switches are installed at each main workstation of the production line for easy operation during the work process.