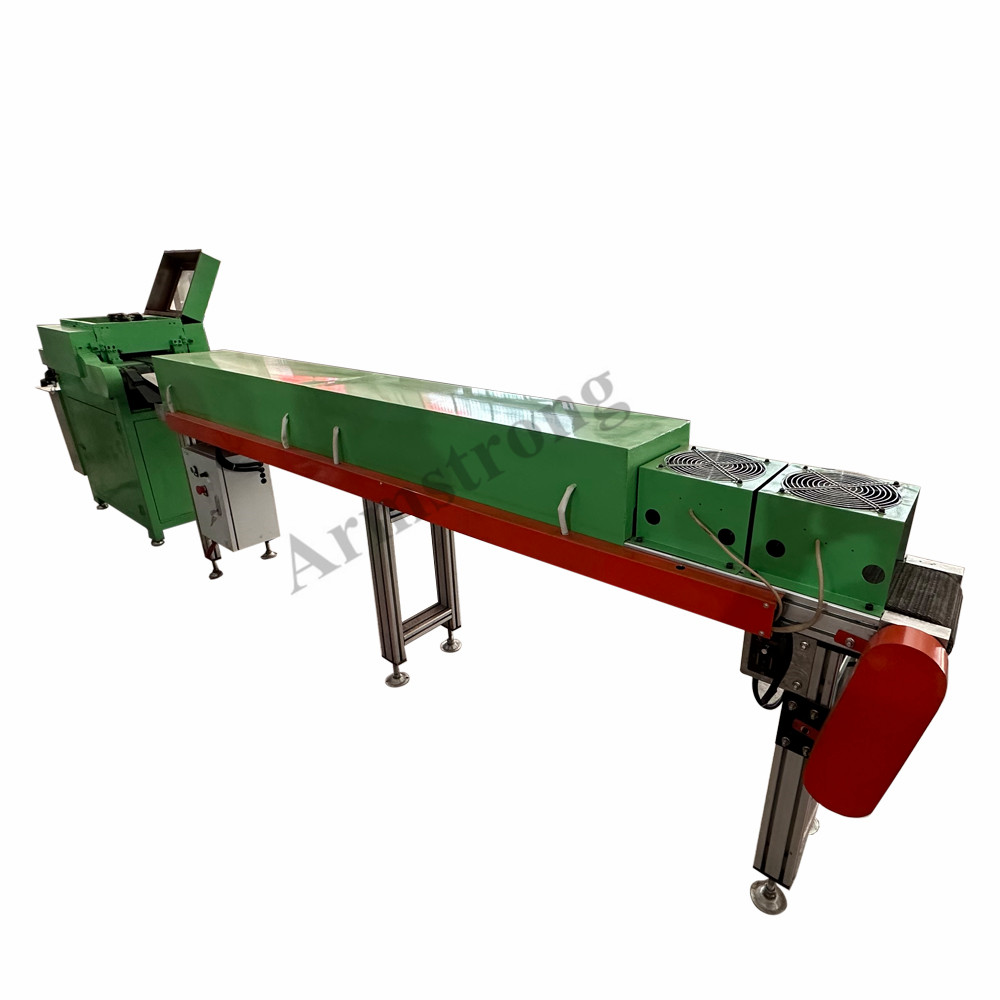

Semi-automatic gluing machine

Application:

Before the brake pad is hot pressed, it is necessary to apply a layer of brake pad back plate glue on the back plate to ensure that the friction material and the back plate have sufficient adhesion after the brake pad is hot pressed, also make the brake pad reach the required shear strength. The commonly used steel back glue coating methods include spraying and rolling. These manually controlled coating method makes the glue thickness on the back plate surface of the brake pad uneven, and the coating quality inconsistent, which can not meet the needs of the existing production process. In view of the shortcomings of the prior art described above, the purpose of the invention is to provide a brake pad back plate gluing device, which is used to solve the problem of poor gluing quality in the prior art.

AGM-605 Steel Back Gluing Machine is applied to the back plate surface of brake pads. The working principle of the machine is that the liquid coating is evenly rolled on the steel back surface, which makes the surface has a layer of glue. The thickness of glue and the feeding speed can be adjusted, meanwhile the brake pads can be placed continuously. It has the characteristics of high efficiency, large output and simple operation, etc. Thus it’s a worthwhile choice for your production needs.

Advantages:

1. Upgrade the single gluing station to two stations, ensuring each back plate surface is coated with glue evenly

2. Use far infrared heating pipes + cooling fan for glue drying, the brake pads won’t stick to each other after output

3. Change gluing roller height from manually to automatically by the air pressure, greatly improving production efficiency

4、The glue supply barrel equipped with agitator, which makes glue evenly and not dry.