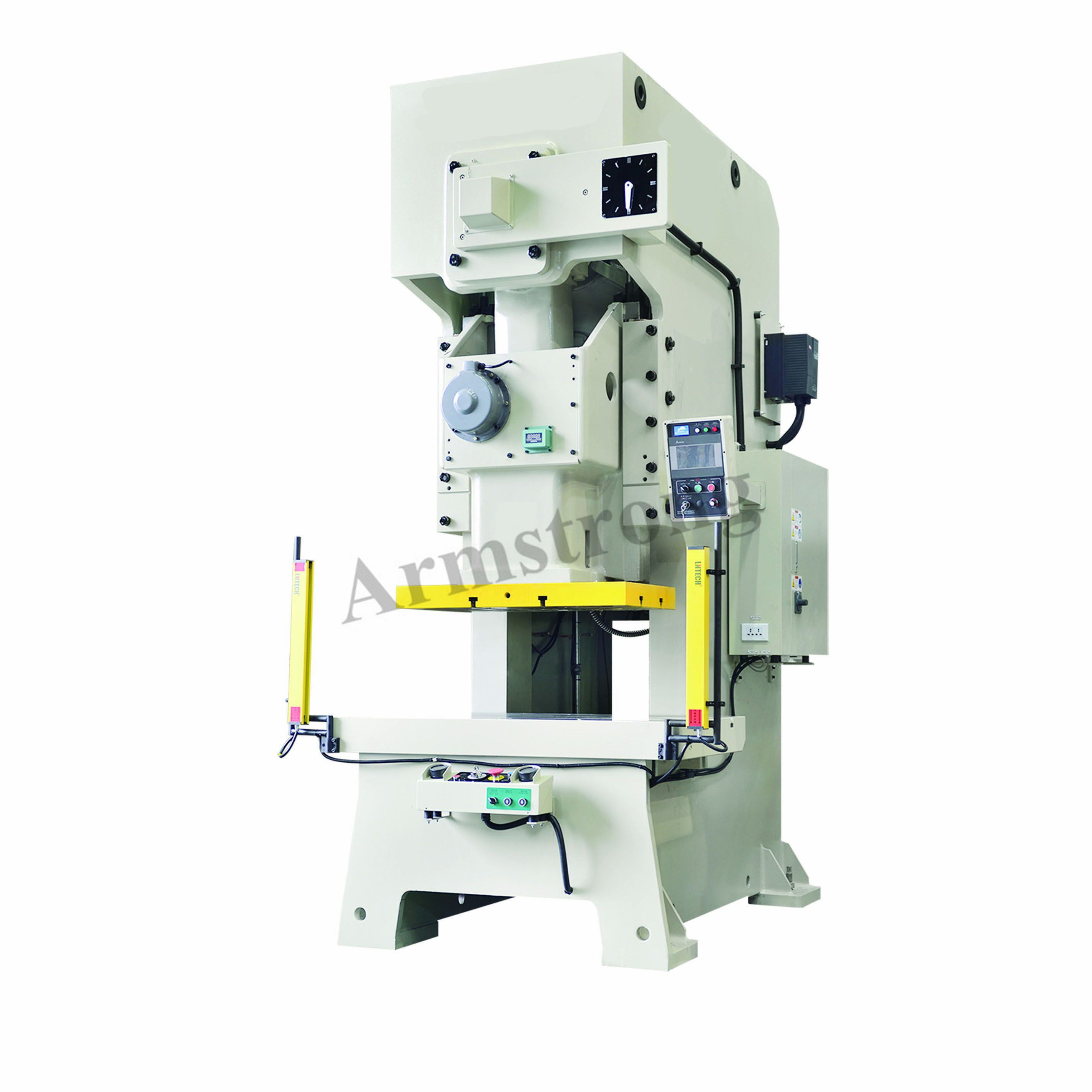

A-PM series Punching machine

Precision high-speed puncher is a high-speed and precise digital control punch, which has the characteristics of high precision, rigidity, efficiency and simple operation. During the operation, the computer-controlled machine converts the circular motion into linear motion, and applies pressure to the material through a series of workmanship to make it plastic deformation, so as to obtain the required shape and accuracy.

The equipment can be widely used in the stamping processing of small precision parts such as back plate punching. It can not only punch the rough back plate on the steel plate, but also press the pins on back plate. For different back plate size and thickness, we designed different puncher models of different pressures. In this way, it can punch the back plate for motorcycle, passenger car and commercial vehicles.

Our Advantages:

1. This equipment can continuously press the steel plate, which has high efficiency. If equip with the automatic feeding device, can greatly increase production capacity.

2. All discs of this series puncher are equipped with advanced dry brake clutches, and the sharp dual solenoid valve (Made from Japanese brand TACO) can shorten the braking time within the limit. In addition, in the event of an emergency, the secondary landing device of the brake assist system will provide the brake signal again to provide the brake signal again to provide enough power to ensure timely and accurate braking.

3. We also pay attention to user’s safety. During the design, the engineer left enough space between the two hand operation buttons of the gantry punch manufacturer and the machine body to protect the safety of hands. At the same time, it was stipulated in the system design that only two hand operation at the same time can start the machine, so as to avoid personal injury caused by misoperation. The installation of photoelectric protection devices or protective nets further improves the protection of users.

4. Die protection: All punchers equipped with overload devices to protect the dies from deformation and damage caused by overload stamping. A misdelivery detection device is also installed to cooperate with the automatic stamping die device to better protect the dies.

Partial technical parameters:

|

A-PM110 |

|

|

Description |

SINGLE CRANK PRESS |

|

Pressure capacity |

110 Ton |

|

Rated Tonnage Point |

6 mm |

|

Stroke per minute |

30-60 SPM |

|

Stroke length |

180 mm |

|

Max shut die height |

360 mm |

|

Slide adjustment |

80mm |

|

Min shut die height |

280 mm |

|

Slide plate(L*W*T) |

910*470*80 mm |

|

Bolster plate(L*W*T) |

1150*600*110 mm |

|

Die Shank Hole Dia |

Φ50 mm |

|

Main motor |

11 kW *4 |

|

Air pressure |

6 kg/cm2 |

|

Puncher dimension(L*W*T) |

1900*1300*3200 mm |

|

Weight |

9.6 Ton |

|

A-PM160 |

|

|

Description |

SINGLE CRANK PRESS |

|

Pressure capacity |

160 Ton |

|

Rated Tonnage Point |

6 mm |

|

Stroke per minute |

20-50 SPM |

|

Stroke length |

200 mm |

|

Max shut die height |

460 mm |

|

Slide adjustment |

100mm |

|

Slide plate(L*W*T) |

700*550*90 mm |

|

Bolster plate(L*W*T) |

1250*800*140 mm |

|

Die Shank Hole Dia |

Φ65 mm |

|

Main motor |

15 kW *4 |

|

Air pressure |

6 kg/cm2 |

|

Puncher dimension(L*W*T) |

2300*1400*3800 mm |

|

Weight |

16 Ton |