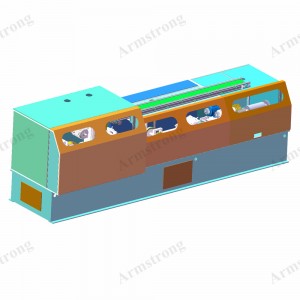

Medium-size Lining Combined Grinding Machine

Working flow:

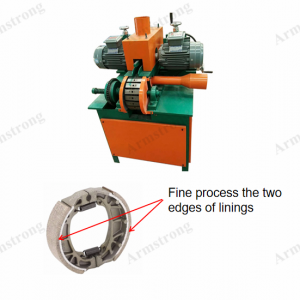

Feed in → Make chamfer → Outer arc grinding → Inner arc grinding → Cutting into single piece → Discharging

Pls note: the machine is used to process medium-size lining, the cutter station can split the lining into 3-4 pieces. If customer want to process long lining piece, need to use long lining cutter split first, and send the single lining to combined grinding machine.

The long lining work flow is as below:

1.Use long cutting machine to split the lining

2.Feed in → Make chamfer → Outer arc grinding → Inner arc grinding → Discharging

Advantages:

1.Compared with current production, the present invention reduces the number of manual labor required for processing and production from 3 to 1, and one person can operate 2-3 machine tools. The labor cost is greatly reduced.

2.Efficiency has been improved, with a production capacity of ≥ 30000 pieces per shift per 8 hours.

3.The operation is simple, and the manual labor intensity has been significantly reduced.

|

Technical Specifications |

|

|

Outer arc mechanism |

2-Pole Motor, 5.5kW |

|

Inner arc mechanism |

2-Pole Motor, 3kW |

|

Chamfer mechanism |

2-Pole Motor, 2.2kW, 2PCS |

|

Cutter mechanism |

2-Pole Motor, 3kW |

|

Grinding wheel |

Surface coated with diamond sand |

|

Labor request |

1 person |

|

Overall dimension |

4400*1200*1500 mm |

|

Total power |

23.5 kW |

|

Machine wight |

3000 KG |

Video