Brake pad shear strength: the invisible guardian of safe driving

Brake pads, as key components of automotive braking systems, have a direct impact on driving safety in terms of their performance. Shear strength is one of the important indicators for measuring the performance of brake pads, which refers to the ability of brake pads to resist forces parallel to the friction surface during the braking process. Strong shear strength means that brake pads can better resist the shear stress generated during the braking process, prevent brake pad cracking, detachment and other failure situations, thereby ensuring the stability and reliability of the braking system.

Shear strength test

So, what factors affect the shear strength of brake pads?

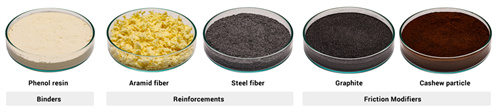

- 1. Materials

1.1 Unqualified friction material: Bad quality of friction material or improper formulation, affecting shear strength.

1.1 Insufficient adhesive glue: The amount of adhesive glue is insufficient or the quality is poor, resulting in the friction material and the back plate is not firmly bonded.

Back plate gluing affect

- 2. Manufacturing process problem

2.1 Improper pressing: Improper control of temperature, pressure or time during the pressing process affects the combination of materials.

2.2 Improper Curing: The curing temperature or time is not appropriate, resulting in insufficient combination of materials.

2.3 Improper surface treatment: The back plate surface treatment is insufficient, if it is not clear or with dust, will affecting the bonding effect.

- 3.Design issue

3.1 Unreasonable structure: The pack plate design is unreasonable, resulting in uneven stress distribution.

3.2 Improper thickness: brake pads are too thick or too thin, affecting shear strength.

- 4.The using environmental issues

4.1 High temperature effect: Binder failure at high temperature, resulting in material separation.

4.2 Corrosive environment: Corrosive environment weakens the material bonding force.

- 5. Installation problem

Improper installation: The installation does not operate according to the specifications, resulting in stress concentration or improper combination.

- 6. Back plate problem

6.1 Poor Back plate material: back plate material strength is insufficient, affecting the overall shear force.

6.2 Improper Back plate surface treatment: improper surface treatment affects the combination with the friction material.

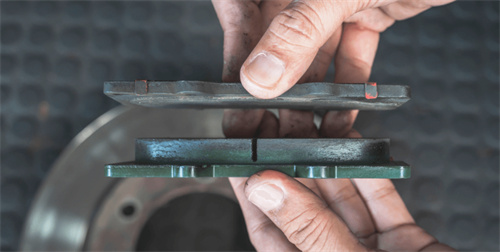

- 7. Aging problem

Long-term use: After long-term use, the material ages and the bonding force decreases.

After long time use

Solution:

-Optimize materials: Select high-quality friction materials and adhesive glue.

- Improved process : Strict control of Pressing and Curing process parameters.

- Reasonable design : Optimize brake pad structure design.

- Improve the environment : Avoid use in extreme environments.

-Standard installation : Ensure that the installation complies with the standard.

-Regular inspection: Regular inspection and replacement of aging brake pad.

Through these measures, the shear force of the brake pads can be effectively improved.

Post time: Mar-28-2025