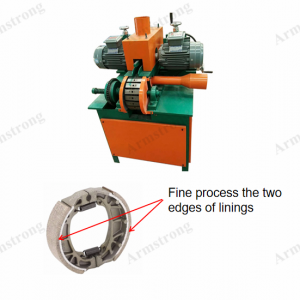

Inner Arc Grinding Machine

1.Function:

Inner arc grinding of motorcycle brake shoe linings is a specialized machining process aimed at improving the shape and performance of brake shoe linings. By precise grinding of the inner arc, it is possible to ensure more even contact between the brake shoe lining and the brake disc, thereby improving the stability and response speed of the brake. In addition, inner arc grinding also helps to extend the service life of brake shoe linings and reduce the risk of brake failure caused by uneven wear.

2.Advantages:

Improve braking efficiency: Through internal arc grinding, the contact area between the brake shoe lining and the brake disc increases, and the friction force distribution becomes more uniform, thereby improving the efficiency of braking.

Enhanced braking stability: The ground brake shoe lining can better fit the brake disc, reduce jumping and noise during braking, and improve braking stability.

Extended Service Life: Uniform grinding can reduce local excessive wear and prolong the overall service life of brake shoe linings.

|

Technical Specifications |

|

| Function |

Brake shoe inner arc grinding |

| Operation |

Manual feeding |

| Grinding head motor |

2-3 kW |

| Grinding wheel |

Rubber wheel |

| Rubber wheel reducer |

1:40, 0.75kW |

Video