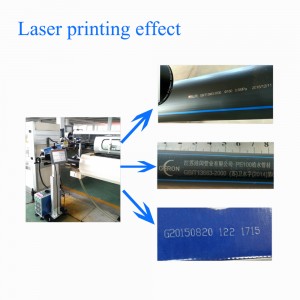

Laser Engraver fiber laser printing machine

Application:

Product identification and traceability: The online laser marking machine can directly engrave product serial number, batch number, production date and other information on the surface of the product, achieving product identification and traceability. This is of great significance for quality control, after-sales service, and product tracking.

Anti counterfeiting and traceability: Laser marking technology can achieve small and difficult to imitate markings on products, and can be applied in the fields of anti-counterfeiting and traceability. to ensure the brake pads authenticity and safety.

Component marking: Laser marking machines can mark product components for easy tracking and management.

Advantages:

Efficient production: The assembly line design enables the laser marking machine to seamlessly connect with the production line, achieving continuous product marking. Compared to manual marking or individually operated marking machines, it can greatly improve production efficiency and quickly complete marking tasks.

Automation operation: The assembly line laser marking machine can be integrated with automation equipment to achieve fully automatic operation, saving time and labor costs for manual operation. Workers only need to place the product on the conveyor belt, and the entire marking process is automatically completed by the machine.

Accurate marking: Laser marking technology has very high accuracy and stability, which can achieve precise marking effects. The assembly line laser marking machine is equipped with a professional control system and laser head, which can accurately engrave marking patterns or text on the product, ensuring marking quality.

High flexibility: The assembly line laser marking machine can be adjusted and configured according to the shape and size of different products. Equipped with functions such as height adjustment, position adjustment, and module switching to adapt to the positioning and labeling needs of different brake pads.