Lining Cutter Machine

The motorcycle brake shoe lining is vest small and short. Normally we has three types for pressing, and two types will use cutter machine.

1.Single lining piece:

Use multi cavity mold, the lining part directly press into small and short part, no need to cut again. But when material pouring into mold cavity, it takes longer time. The workers need to leveling each cavity’s material, during the leveling process, some cavities material has been solid without press, the product quality not so stable.

Multi cavity press mold for brake shoe

2.Medium lining piece

Use multi-layers mold, each layer can press 1-2 medium size lining. After pressing, the lining can cut into 3-4 pieces.

Multi layer press mold for brake shoe

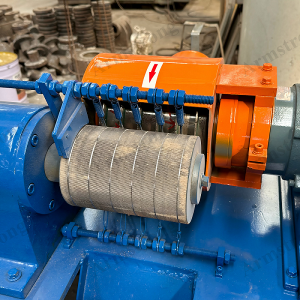

Medium lining cutter

Video

3.Long lining piece

Use long strip mold, the mold normally has 2 cavities. Pour materials into cavities and press it, after pressing the shoe lining can cut into 10-15 pieces.

Long lining piece

Long lining piece

Video

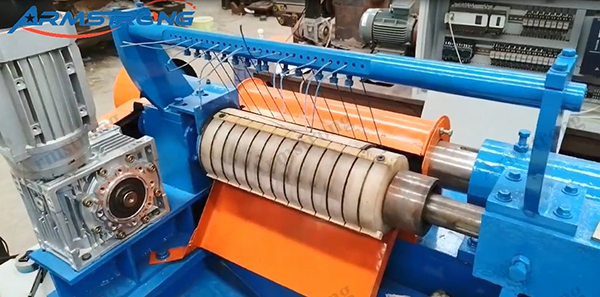

The cutter machine can rapidly split the medium or long lining into multiple pieces. The split width is adjustable and efficiency is very high.

|

Technical Specifications |

|

| Function |

Cut the medium/long brake lining into multi pieces |

| Operation |

Manual feeding |

| Piece width |

Adjustable |

| Grinding head motor |

2-3 kW |

| Main spindle motor |

250W |