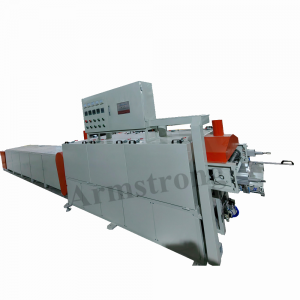

Hydraulic 4 column hot press machine

Hot Press Machine is specially served for brake pad of motorcycle, passenger car and commercial vehicles. Hot pressing process is a crucial process in the production of brake pads, which basically determines the final performance of brake pads. Its actual action is to heat and cure the friction material and back plate through adhesive. The most important parameters in this process are: temperature, cycle time, pressure.

Different formulas has different parameter specifications, so we need to settle the parameters on the digital screen according to the formula at the first using. Once the parameters has been settled, we just need to press three green buttons on panel to operate.

In addition, different brake pads has different size and pressing requirement. Thus we designed the machines with pressure in 120T, 200T, 300T and 400T. Their advantages mainly include low energy consumption, low noise, and low oil temperature. The main hydro-cylinder adopted no flange structure to improve the leak resistance performance.

Meanwhile, the high hardness alloy steel is used for the main piston rod to increase the wear resistance. The totally enclosed structure for the oil box and electric box are dust-proof. What’s more, the loading of the sheet steel and the brake pad powder are done out of the machine to ensure the operation safety.

During the pressing, the middle mold will be locked automatically to avoid the leaking of the material, which is also beneficial to increase the aesthetics of pads. The bottom mold, the middle mold, and the top mold can move automatically, which could make full use of the mold area, improve the production capacity and save labor.