Machining Center

Daim ntawv thov:

Ua kom zoo txheej txheem rov qab phaj tom qab laser txiav.Yog tias siv lub tshuab laser txiav rau blanking thiab ua qhov, lub phaj rov qab loj yuav muaj qhov sib txawv me me, yog li peb siv qhov chaw machining kom zoo txheej txheem rov qab phaj raws li daim ntawv thov.

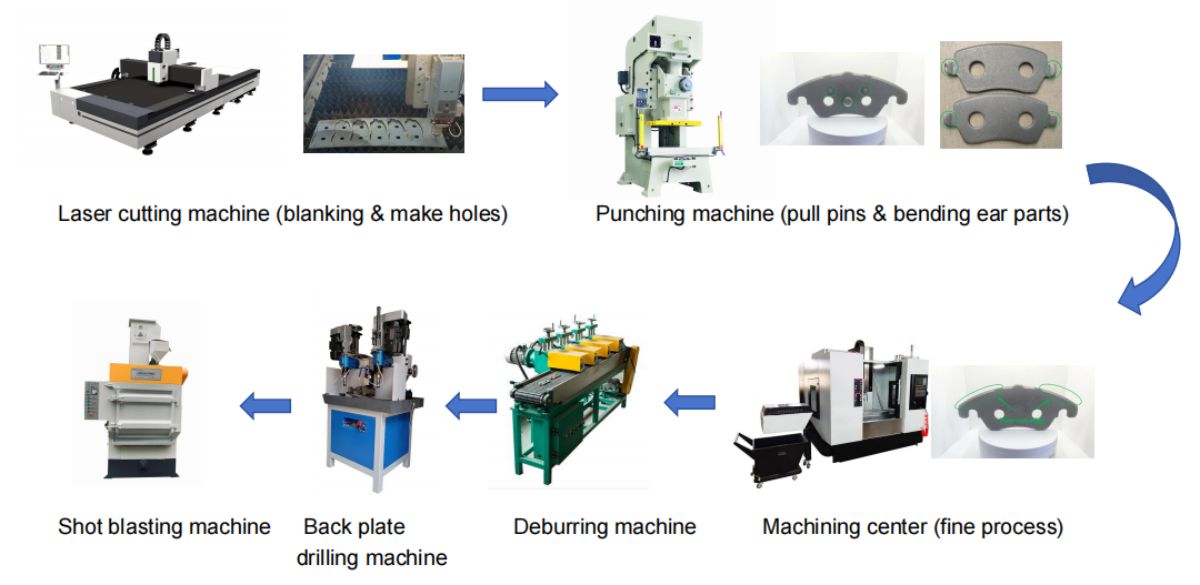

PC Back Plate Production Flow

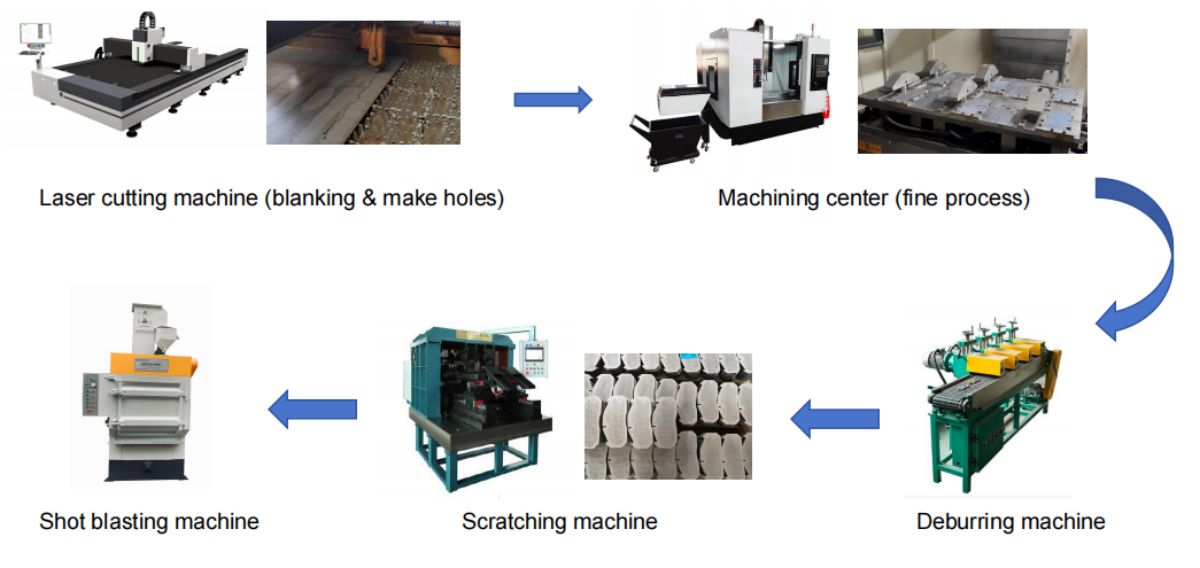

CV Back Plate Production Flow

Peb qhov zoo:

Muaj zog rigidity: spindle txoj hauj lwm ntawm ntsug machining chaw yog siab dua, thiab lub phaj nraub qaum yog clamped rau ntawm lub workbench, ua rau cov txheej txheem machining nruj dua thiab muaj peev xwm tuav ntau dua cov phaj rov qab thiab siab dua txiav quab yuam.

Zoo machining stability: Vim lub siab dua spindle txoj hauj lwm ntawm ntsug machining chaw, lub machining thiab txiav txheej txheem ntawm lub nraub qaum phaj yog ruaj khov dua, uas yog qhov zoo rau kev txhim kho machining raug thiab nto zoo.

Kev ua haujlwm yooj yim: Workpiece clamping thiab cov cuab yeej hloov pauv tau ua tiav ntawm qhov chaw ua haujlwm, ua kom yooj yim rau cov neeg ua haujlwm saib xyuas thiab tswj.

Cov hneev taw me me: Lub chaw machining ntsug muaj cov qauv tsim thiab cov hneev taw me me, ua rau nws tsim nyog rau kev cob qhia nrog qhov chaw tsawg.

Tus nqi qis: Yog tias siv lub tshuab xuas nrig ntaus rau cov txheej txheem rov qab phaj zoo, peb yuav tsum ua kom zoo txiav stamping tuag rau txhua tus qauv, tab sis machining chaw tsuas yog yuav tsum muaj lub clamp los tso cov phaj rov qab.Nws tuaj yeem txuag pwm kev nqis peev rau cov neeg siv khoom.

Kev ua haujlwm siab: Ib tus neeg ua haujlwm tuaj yeem tswj tau 2-3 teeb machining chaw tib lub sijhawm.