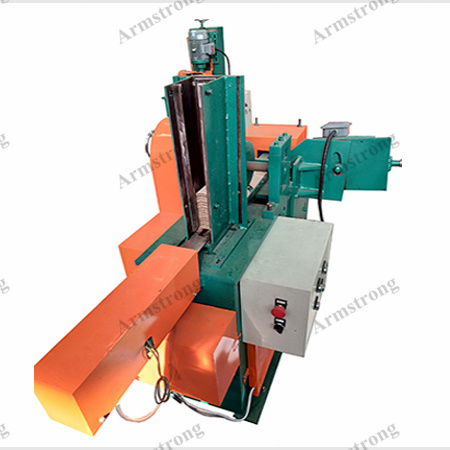

Chamfering Machine

The purpose of make chamfers on motorcycle brake shoes mainly includes the following points:

1. Noise Reduction: Chamfer treatment can reduce the sharpness of the lining edges, minimizing the vibration or harmonics generated during the braking process, thereby reducing the noise generated during braking and providing a quieter riding experience.

2. Improving brake shoe wear: The edges of the chamfered brake shoes become smoother, allowing for more thorough and even contact with the brake disc, helping to evenly distribute braking force on the surface of the brake linings, avoiding premature or uneven wear, and extending the service life of the brake shoes.

3. Heat dissipation: During the braking process, a large amount of heat is generated. Chamfer treatment can improve airflow, reduce thermal stress, help brake pads dissipate heat, and prevent brake performance degradation caused by overheating.

4. Provide a smooth braking experience: The chamfered edges of the brake shoes are smooth, helping them to make smooth contact with the brake disc, avoiding sudden vibrations or stops, enhancing overall control and maneuverability, and providing a safer and more enjoyable riding experience for riders.

|

Technical Specifications |

|

| Function |

Brake lining chamfering |

| Operation |

Manual feeding |

| Grinding head motor |

2-2.2 kW |

| Rubber wheel reducer |

1:121, 0.75kW |

Video