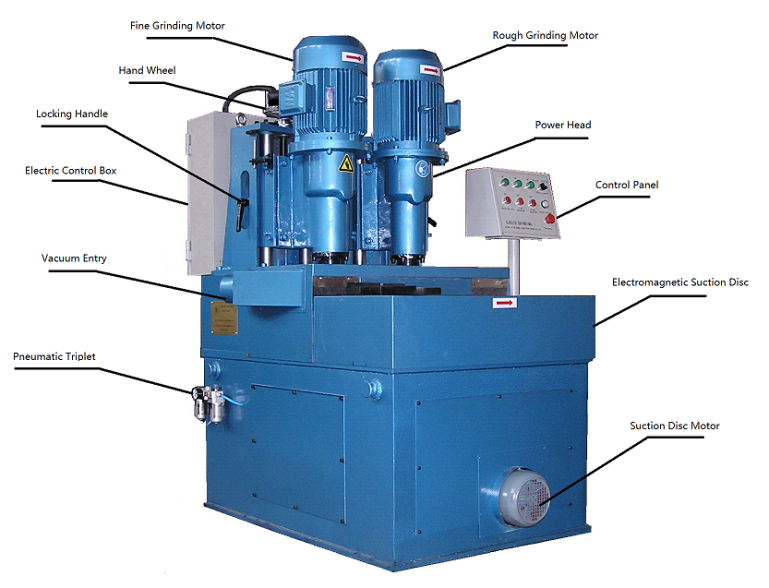

Disc Grinding Machine – Type A

1. Characteristics:

Disc pads grinder is simple to operate and easy to adjust. It uses electro-magnetic disc to pull in and release automatically in zones. It could pull in and release continuously and is highly efficient.

Upper and lower adjustment uses V-shape track.

2. Design drawings:

3. Working principle:

Before operation, open wind source for dust blow and dust vacuum. Then activate electric magnetic suction disc, speed motor and grinding motor. Adjust electric magnetic suction disc rotation speed and grinder height according to requirement. Place back plates in loading areas of workbench. (The workbench has grooves that can accommodate the protrusions on the back plate). Back plates is turned into magnetic area and attracted. Through rough grinding, fine grinding, the back plate enters demagnetization zone for manual removal of the back plate. This process can work continuously.

4.Application:

The disc grinder is special equipment for the grinding of disc brake pads friction material surface. It is suitable to grind all kinds of disc brake pads, controlling friction material surface roughness and ensure parallelism requirement with back plate surface. The special structure of round plate (ring groove) is suitable to grind brake pads with convex hull back plate.