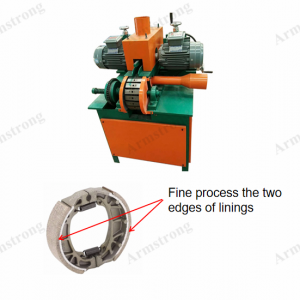

Brake shoe assembly outer arc grinding machine

Application:

To grind the drum brake outer arc after assembly, make the finished brake shoe size more accurate, and better fit the drum brake.

After the lining and metal part bonded together, brake shoe assembly will enter the curing oven or heating channel for better bonding effect. During the high temperature curing, the lining friction part may expand by chemical reaction, the outer arc size would has slightly deformation. Thus to make high quality and better appearance product, we’ll use assembly outer arc grinding machine to fine process the brake shoe again.

Machine workflow:

1. Install the assembly on fixture manually

2. Press the foot switch and pneumatic clamp the assembly

3. Press work button, machine auto grind 1-2 laps

4. Fixture auto stop rotating, cylinder auto releases the fixture

5. Unload the brake shoe assembly

Advantages:

2.1 High Efficiency: The tooling fixture can hold 2 pcs brake shoe and grind at same time. When grinding the worker can work on other grinding machine. One staff can hold 2 machines per shift.

2.2 Flexibility: The machine tooling fixture is adjustable, it adapts various brake shoe models for grinding. The fixture adjustment is also very easy.

2.3 High Precision: The grinders adopts high accuracy grinding wheel, which can keep the grinding parallel thickness error less than 0.1 mm. It has high machining accuracy and can meet the requirements of OEM shoe lining production request.

Video