Brake pad mold

Composition of Hot Press Mold for Brake Pads

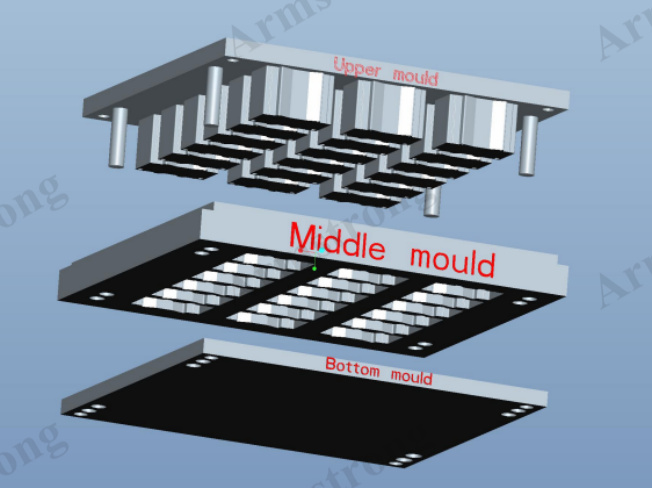

The hot press mold for brake pads usually consists of the following parts:

1.Upper, middle and bottom molds: This is the main part of the mold, responsible for applying pressure and maintaining shape during the hot pressing process. The design of the upper, middle and bottom molds requires precise matching to ensure the dimensional accuracy and surface quality of the brake pads. Put the back plate on bottom mold, pour raw material in middle mold cavities, and use upper mold’s matrix to press.

2. Heating element: In order to achieve the required hot pressing temperature, the heating tubes is usually installed in the press machine, and the heat will be heated by heat conduction. These heating elements can quickly and uniformly heat the mold for efficient hot pressing.

3. Guidance and positioning components: These components ensure that the upper and lower molds can be accurately aligned during the hot pressing process, avoiding deviations or misalignment that may affect the geometric accuracy of the brake pads.

Working principle of hot pressing mold for brake pads:

1. Preheating: Firstly, the mold is preheated to a set temperature through heating tubes on press machine.

2. Loading: Place the back plate on bottom mold, and pour mixed brake pad materials in the middle mold cavities.

3. Mold closing hot pressing: The upper mold descends and the lower mold closes, while applying a certain amount of pressure. Under the action of high temperature and high pressure, the raw materials begin to shape and gradually form the final shape of the brake pads.

4. Pressure holding cooling: After degas as material technical sheet request, maintain a certain pressure while starting curing.

5. Mold removal: After the curing, open the mold and remove the finished brake pads.

The importance of hot pressing molds for brake pads:

As a key component of the automotive braking system, the performance of brake pads directly affects the safety and driving experience of the vehicle. The accuracy and reliability of hot pressing molds determine the physical and chemical properties of brake pads, such as friction coefficient, wear resistance, thermal stability, etc. Therefore, high-quality hot pressing molds are the cornerstone for producing high-performance brake pads.

Video