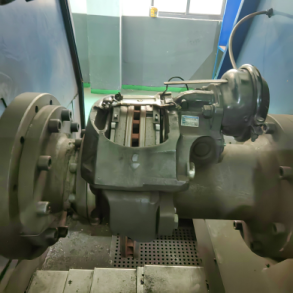

Car Brake Pad Dynamometer – Tpye A

1. Application:

This integrated dynamometer uses horn brake assembly as the test object, and simulates inertia loading by mixing mechanical inertia and electrical inertia to complete brake performance testing. The brake dynamometer can realize the braking performance appraisal and evaluation test of various types of Passenger cars, as well as the braking performance test of automobile brake assemblies or braking components. The device can simulate the real driving conditions and the braking effect under various extreme conditions to the greatest extent, so as to test the real braking effect of the brake pads.

2. Advantages:

2.1 The host machine and test platform adopt the similar bench technology of German Schenck company, and there is no foundation installation method, which not only facilitates the installation of equipment, but also saves a large amount of concrete foundation cost for users. The damping foundation adopted can effectively prevent the influence of environmental vibration.

2.2The flywheel inertia adopts a mechanical and electrical hybrid simulation method, which not only has a compact structure but also achieves effective compensation for stepless loading of inertia and bearing loss.

2.3 The sliding ring installed at the spindle end can achieve temperature measurement of rotating parts

2.4 The static torque device automatically disengages and interlocks with the main shaft through the clutch, and the speed is continuously adjusted.

2.5 The machine adopts Taiwan Kangbaishi hydraulic servo brake pressure generation system, which operates stably and reliably with high precision in controlling pressure.

2.6 The bench software can execute various existing standards, and is ergonomically friendly. Users can compile test programs by themselves. The special noise test system can run independently without relying on the main program, which is convenient for management.

2.7 The typical standards that the machine can execute are as follows:

AK-Master,VW-PV 3211,VW-PV 3212,VW-TL110,SAE J212, SAE J2521, SAE J2522,ECE R90, QC/T479,QC/T564, QC/T582, QC/T237, QC/T239, JASO C406,JASO C436,Ramp,ISO 26867, etc.

3. Technical Parameter:

|

Main Technical parameters |

|

| Motor power | 160kW |

| Speed range | 0-2400RPM |

| Constant torque range | 0-990RPM |

| Constant power range | 991-2400RPM |

| Speed control accuracy | ± 0.15%FS |

| Speed measure accuracy | ± 0.10%FS |

| Overload capacity | 150% |

| 1 Inertia system | |

| Test bench foundation inertia | Around 10 kgm2 |

| Dynamic inertia flywheel | 40 kgm2 * 1, 80 kgm2 * 2 |

| Maximum mechanical inertia | 200 kgm2 |

| Electrical analog inertia | ±30 kgm2 |

| Analog control accuracy | ±2 kgm2 |

| 2 Brake drive system | |

| Maximum brake pressure | 21MPa |

| Maximum pressure rise rate | 1600 bar/sec |

| Brake fluid flow | 55 ml |

| Pressure control linearity | < 0.25% |

| 3 Braking torque | |

| The sliding table is equipped with a load sensor for torque measurement, and the full range | 5000 Nm |

| Measurement accuracy | ± 0.2% F.S. |

| 4 Temperature | |

| Measuring range | -25℃~ 1000℃ |

| Measurement accuracy | ± 1% F.S. |

| Compensation line type | K-type thermocouple |