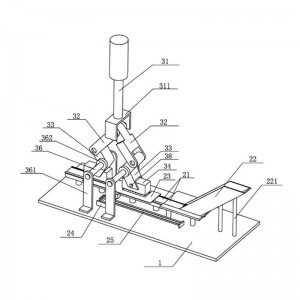

Back Plate Scratching Machine

Application:

For commercial vehicle, the loading weight and inertia is very big, so it has higher standard for brake performance. In order to enhance the shear strength of CV brake pad, we would add some special techniques to the back plate. It mainly has 3 types: mesh type, holes type and scratching type.

Protrusion extruded on back plate of brake pad is a necessity to protect brake linings from break-off by enhancing shear force. This CNC back plate scratching machine can scratch 2 back plates at same time, and automatically work according to settled program.

Scratch effect

Our advantages:

2.1Double work station: The scratching machine is equip with 2 work stations, it can process 2 back platesat same time. The efficiency is very high, can make 280 pcs back plate per hour.

2.2CNC control: The scratching point amount and scratches interval are all adjustable, the machine will process as program settled. CNC control ensures high scratching precision, and also make back plate appearance looks better.

2.3Safety consideration:The machine equips plastic shield on the work station, and install alarm device to prevent dangers. If the worker open the plastic shield, the machine will stop work.

2.4Easy operation: The machine equips a set of tooling and automatic feeding device. It can auto grab theback plate, after processing the finished back plate will auto slipped to discharge area. One worker can handle 2-3 machines at same time, save the labor cost.