Automatic powder coating line

1. Application:

PCM-P601 High Infra-red Electrostatic Spray Coating Line is mainly composed of powder spraying booth, recycling box, powder screening device, high infra-red drying tunnel, cooling machine, and this professional equipment is applicable to the surface spraying of disc brake pads of various vehicles .

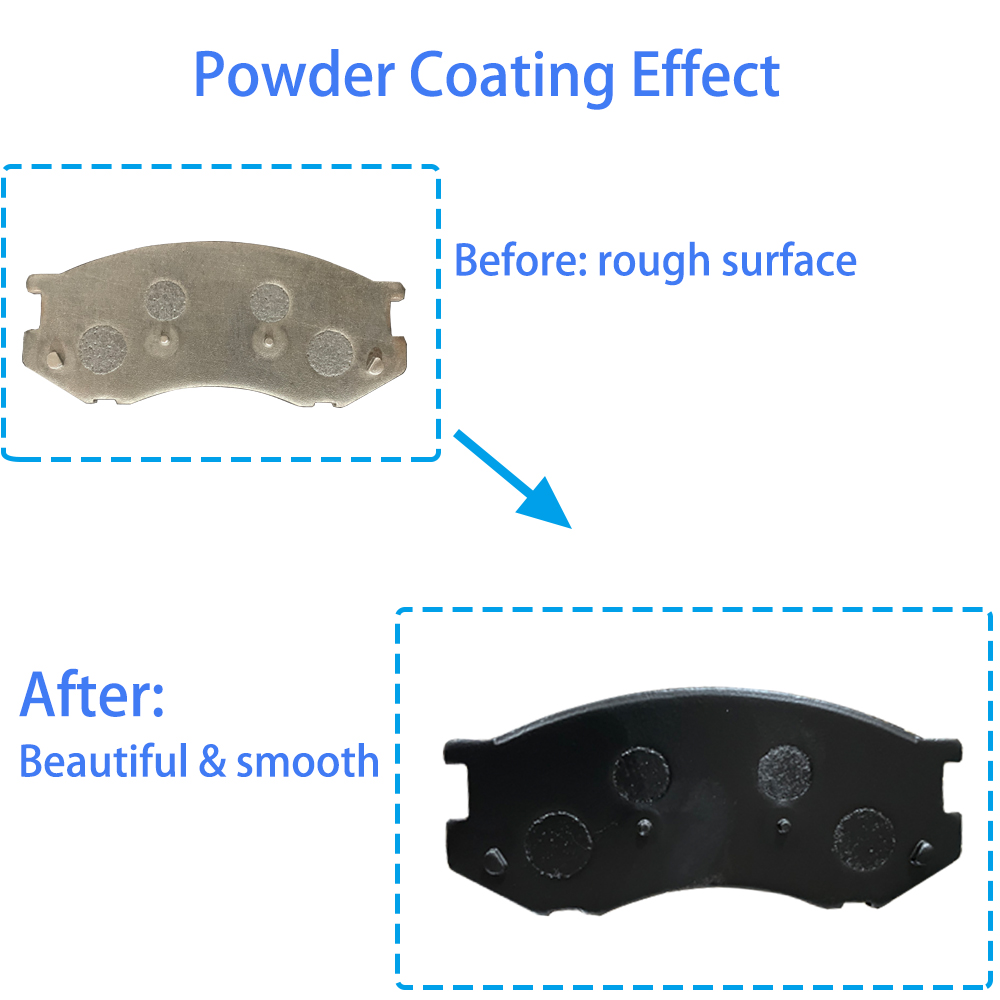

It works to send a certain amount of charge on the plastic powder, evenly adsorb the plastic powder on the material surface by electrostatic adsorption, and evenly bond the plastic powder on the product surface through high-temperature melting, leveling, curing, cooling and other processes, so as to achieve the anti-corrosion and anti rust function of the product. The equipment has high production efficiency and stable quality, which is suitable for the needs of mass production. At the same time, it has the characteristics of simple operation, fast powder change, integrated recycling and reusing, continuous feed the brake pads, etc. Thus it’s a worthwhile choice for your production needs.

2. Our advantages:

The powder spraying line adopts high infra-red drying channel. The advantages of this channel lies in the following aspects:

1. It saves 20% energy compared with the ordinary drying channel with the same power. (the ordinary drying channel transmits heat in the form of heat conduction, while the high infra-red is transmitted in the form of radiation. The utilization rate of energy is increased by 20% - 30%.)

2. The heating speed is very fast. It takes only 8-15 minutes to rise from normal temperature to 200 ℃ ( it usually takes 30-40 minutes for the ordinary drying channel to rise in the same condition, so there is no need to wait for time in the production process, manufacturers just open and directly use.)

3. The drying tunnel is short and the site is saved (the high infra-red is heated by radiation, so the product surface heats up quickly. And the plastic powder, paint and glue can melt the sulfur level in 1-2 minutes, while the internal heat of the product is very low, which has the purpose of saving energy and speed up for the surface spraying industry.) In addition, the cross cut test and the salt spray 72 hour test are qualified.

4. It plays a rapid function in the subsequent cooling of the product (due to the high surface temperature and low internal temperature of the product)

3. Main component:

This equipment mainly contains 3 sections, which are Spraying section, Curing section and Cooling Section:

A. Spraying section:

1. This equipment adopts cold plate box booth, the conveying electrostatic belt adopts 2.5mm all-round conductive belt. The conveyor adopts speed regulating motor and square tube girder, and the lower part of the conveyor belt is fully enclosed 1.5mm stainless steel bottom plate (to ensure the flatness and conductivity of the bottom surface). The transmission shaft is of medium high and two low micro arc design to prevent wrinkling and edge running of the conductive belt. The powder brush box adopts mobile type, and the adjustment of brush roller up and down is simple.

2. The electrostatic gun adopts adjustable motor, the back and forth transmission part adopts closed type to prevent powder overflow. The electrostatic gun and electrostatic generator are both made in Shanghai. (electrostatic gun adopts type 3).

3. The plastic powder recovery device is divided into recovery chamber and vulcanization chamber. Recovery room includes fan room, back blowing room, filter cartridge room and recovery room; The vulcanization chamber is divided into screening powder chamber and vulcanization chamber. The fan room adopts the anti mute design of medium pressure recovery fan, the filter cartridge room adopts 6 filter cartridges with diameter of 280 for filtration, and the back blowing room adopts air back blowing device, which has the back blowing function of 6 clearance cycles; The recovery room is a reverse suction recovery pump; The powder screening chamber is a hollow shaft rotary screen and waste powder discharge device, both ends are sealed with compressed air, and the vulcanization chamber is designed with vulcanization plate and inlaid powder generator. The whole device is designed to seal and prevent dust, so as to eliminate powder dust. The appearance of the equipment is simple, clear and tidy.

B. Curing section:

The design temperature of the oven is 300 ℃, the insulation layer is 100mm, and the speed regulation adopts frequency converter. In addition, the electrical configuration is PLC thyristor power regulator to control the switching value of heating pipe.

C. Cooling section:

After the product is dried and solidified, it enters the air cooling system to cool the brake pad to about 40° (Shanghai fan).

① The cooling fan adopts two 2.2kW pole induced draft fans to forcibly cool the product by means of strong wind and air knife system.

② The machine foot is made of section steel with adjustable foot cup.

③ The total length of the cooling section is 5-6m.