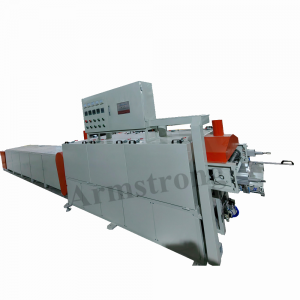

Shot blasting machine 100KG

1. Application:

SBM-P606 Shot Blasting Machine is suitable for surface cleaning of various parts. All kinds of processing procedures can be realized by the shot blasting strengthening process: 1. cleaning the sand sticking on the surface of metal castings; 2. surface derusting of ferrous metal parts; 3. blunting of burr and burr on the surface of stamping parts; 4. surface treatment of forgings and heat treated workpieces; 5. removal of oxide scale on spring surface and grain refinement on spring surface.

It has a wide range of applications, mainly including foundry, heat treatment plant, motor factory, machine tool parts factory, bicycle parts factory, power machine factory, auto parts factory, motorcycle parts factory, non-ferrous metal die casting factory, etc. The workpiece after shot blasting can obtain a good natural color of the material, and can also become the previous process of blackening, bluing, passivation and other processes on the surface of metal parts. At the same time, it can also provides a good base surface for electroplating and paint finishing. After shot blasting by this machine, the workpiece can reduce the tensile stress and refine the surface grain, so as to strengthen the surface of the workpiece and increase its service life.

The equipment also has the advantages of low working noise, less dust and high production efficiency. Meanwhile, the shot can be recycled automatically, with less material consumption and low cost. It is an ideal surface treatment equipment for modern enterprises.

2. Working Principles

This machine is a rubber crawler shot blasting machine. Wear resistant protective plates are laid on the left and right sides of the shot blasting chamber. The shot lifting and separation mechanism separates the shot, broken shot and dust to obtain qualified shot. The shot enters the high-speed rotating shot dividing wheel from the chute of the shot blasting device by its own weight and rotates with it. Under the action of centrifugal force, the shot enters the directional sleeve and is thrown out in the rectangular window of the directional sleeve to reach the high-speed rotating blade. The shot accelerates from inside to outside on the blade surface, and is thrown to the workpiece in a fan shape at a certain linear speed to strike and scrape the oxide layer and binder on its surface, so as to clean the oxide layer and binder.

The energy lost shots will slide down to the bottom of the elevator along the inclined plane below the main machine, then be lifted by the small hopper and sent to the top of the hoister. Finally, they will return to the shot blasting device along the shot chute and work in a cycle. The workpiece is placed on the track and turns over with the movement of the track, so that the surface of all workpieces in the cleaning room can be shot blasted.

The main function of the dust removal mechanism is to participate in the shot separation of the lifting separator and remove the dust generated in the process of dust removal and shot blasting.