Automatic Brake Pad Weighing & Pressing Line

The whole line work logic is as below:

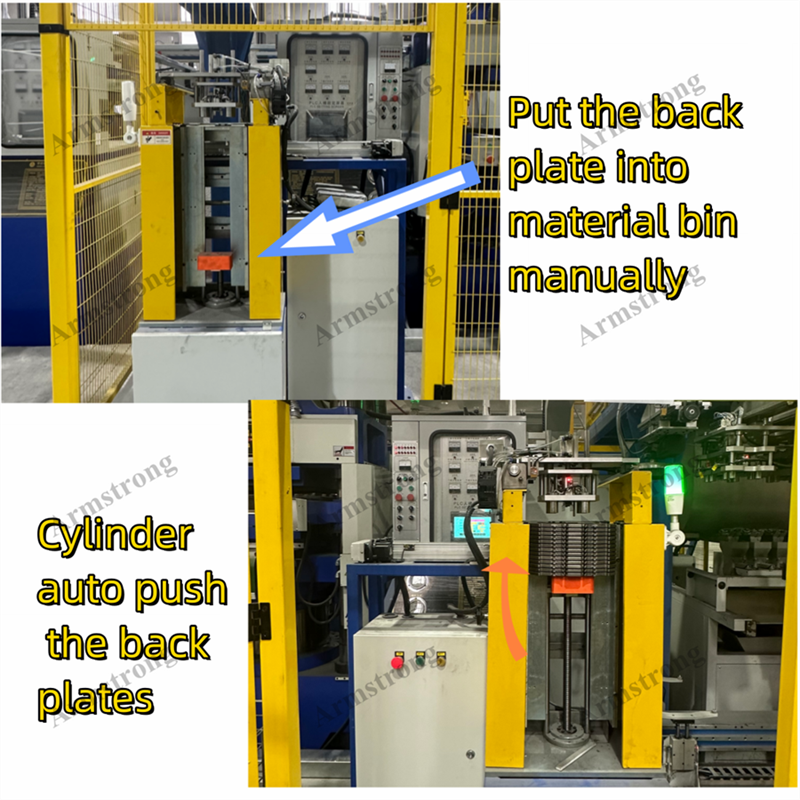

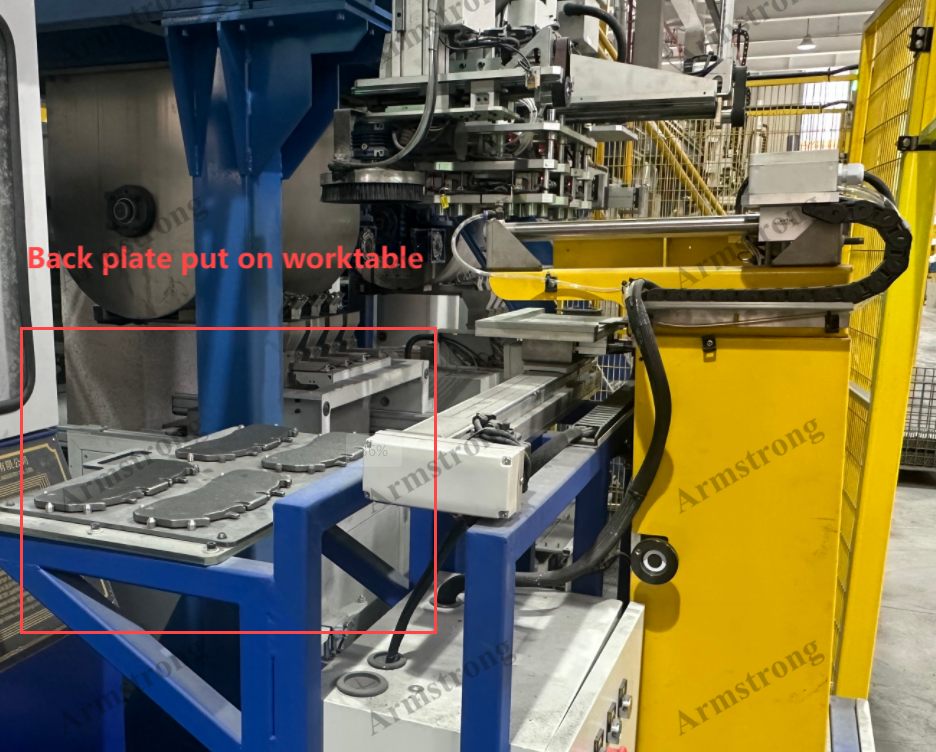

1.Worker put the back plate into back plate bins manually, and the robot magnetically hold the back plates and places it on the back plate work table.

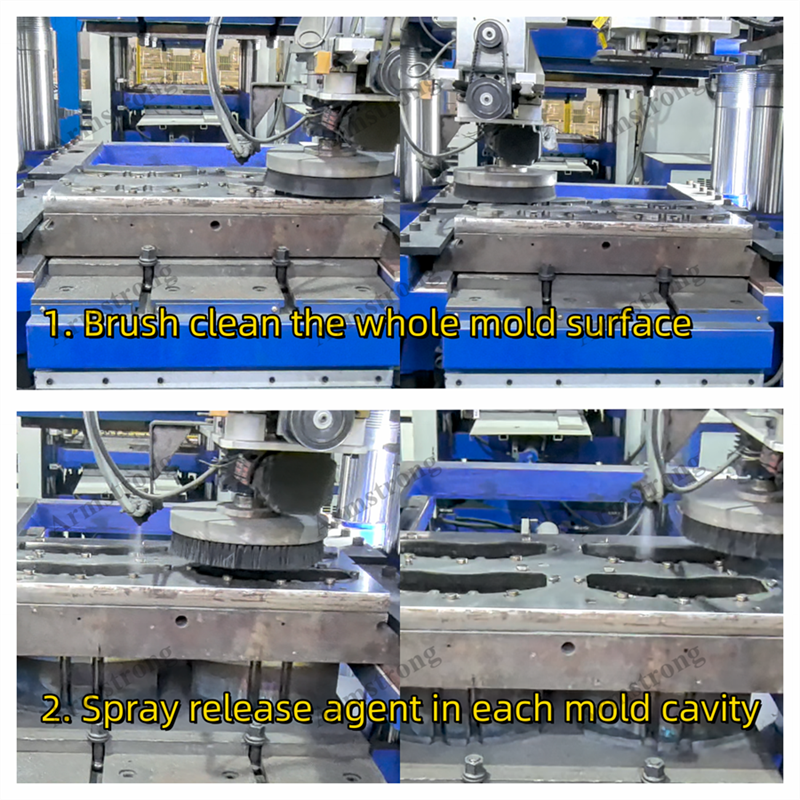

2.Auto weighing the raw material of each cavity

3.Use brush to clean the mold surface & spray release agent in mold cavities.

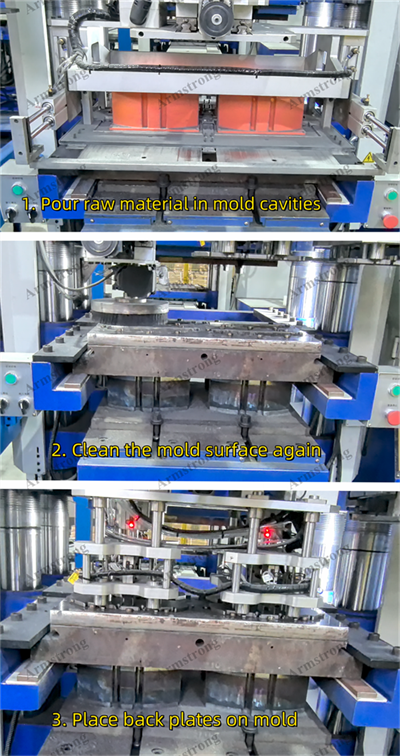

4.Pour raw material into cavities, place back plates on mold & cleaning mold surface

5.Auto Pressing and grab the finished brake pads on worktable

Auto line advantages:

1.One worker can inspect 2-3 lines, low labor demand saves labor costs.

2.The auto line can continuously work in 24 hrs, Non-stop work increase the production efficiency.

3.Each part equip detector device, if any malfunction will trigger an alarm and stop working, reduce the defect rate caused by incorrect production.

4.Material weighing & pouring are finished by auto manipulator, workers not exposed to dusty work environment, it’s more healthy friendly.