Strapping Machine

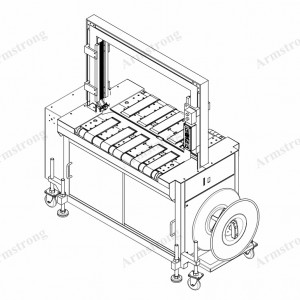

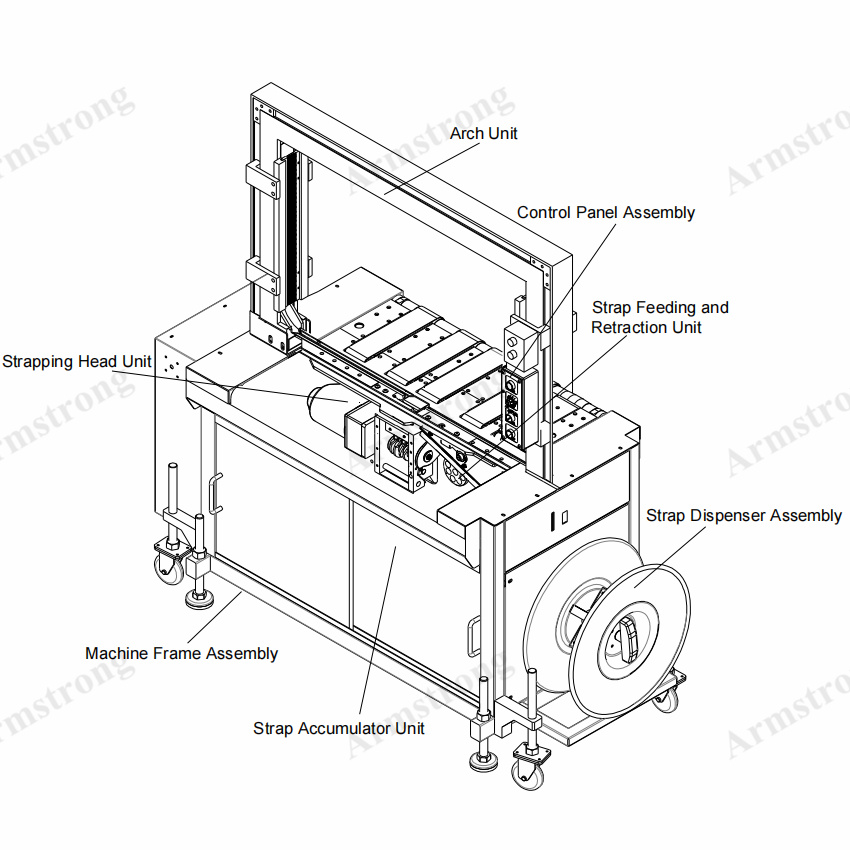

Main components of the machine

Working principle

The strapping machine uses automated mechanical devices to tightly bind plastic strapping onto the cardboard box, ensuring the stability and safety of the goods during transportation. The basic workflow includes:

Carton positioning, strapping supply, strapping wrapping, tightening, cutting, hot melt bonding (for plastic strapping), and finally completing the strapping.

Type

The strapping machine is mainly divided into two types: fully automatic and semi-automatic.

Fully automatic strapping machines are usually equipped with a conveyor belt system that can automatically identify and tie cardboard boxes that have passed through, making them suitable for large warehouses and production lines.

Auto packaging line

The semi-automatic strapping machine requires manual placement of cardboard boxes in designated positions before starting the machine, making it suitable for use by small enterprises.

Single machine type

This strapping machine is fully auto type, it can connect with conveyor belt system for fully auto use. In addition, this machine can also be used alone and supports manual mode.

Advantages

Improve efficiency: Compared with traditional manual bundling, the cardboard box bundling machine greatly improves bundling speed and reduces labor costs.

Quality assurance: The machine bundles more evenly and firmly, ensuring that the goods are not easily loose or damaged during transportation.

Easy operation: Most cardboard box strapping machines are designed to be user-friendly and easy to operate. Employees can start working after simple training.

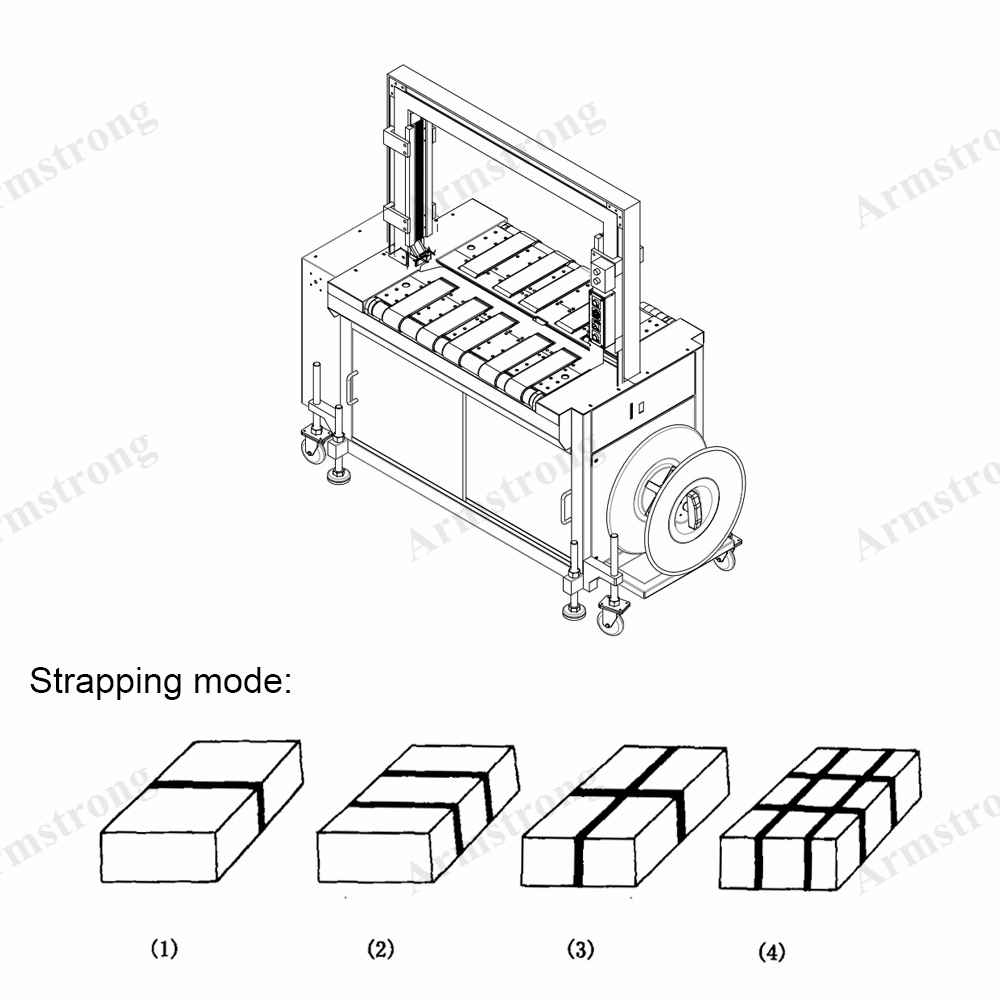

Strong adaptability: The bundling force and method can be adjusted according to different cardboard box sizes and materials to meet diverse packaging needs. It can make 4 types strapping modes, meet different product packing request.

|

Technical Specifications |

|

|

Power |

380V, 50/60 Hz, 1.4kw |

|

Overall dimensions(L*W*H) |

1580*650*1418 mm |

|

Binding size |

Min package size: 210*100mm(W*H) Standard size: 800*600mm(W*H) |

|

Worktable height |

750mm |

|

Bearing capacity |

100kg |

|

Binding speed |

≤ 2.5 seconds / tape |

|

Binding force |

0-60kg (adjustable) |

|

Binding model |

Parallel 1 ~ multiple tapes, including photoelectric control, manual control, etc. |

|

Conveying roller |

It can be transported directly when binding is not required. |

|

Binding tape specifications |

Width: 9-15 (±1) mm, Thickness; 0.55-1.0 (± 0.1) mm |

|

Tape tray specification |

Width: 160-180mm, inner diameter: 200-210mm, outer diameter: 400-500mm. |

|

Binding method |

Hot melt method, bottom binding, binding surface ≥ 90%, bonding position deviation ≤ 2mm. |

|

Weight |

280kg |

|

Optional item |

① Increase the size ② add the press |

|

Electrical configuration |

PLC controller: YOUNGSUN Buttons: Siemens APT Contactor: Schneider Relay: Schneider Motor: MEIWA Photoelectric, proximity switch and other sensors: YOUNGSUN |

|

Noise |

in working environment: ≤ 80dB (A) |

|

Environmental requirement |

Humidity ≤ 98%, Temperature: 0-40 ℃ |

Video