- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

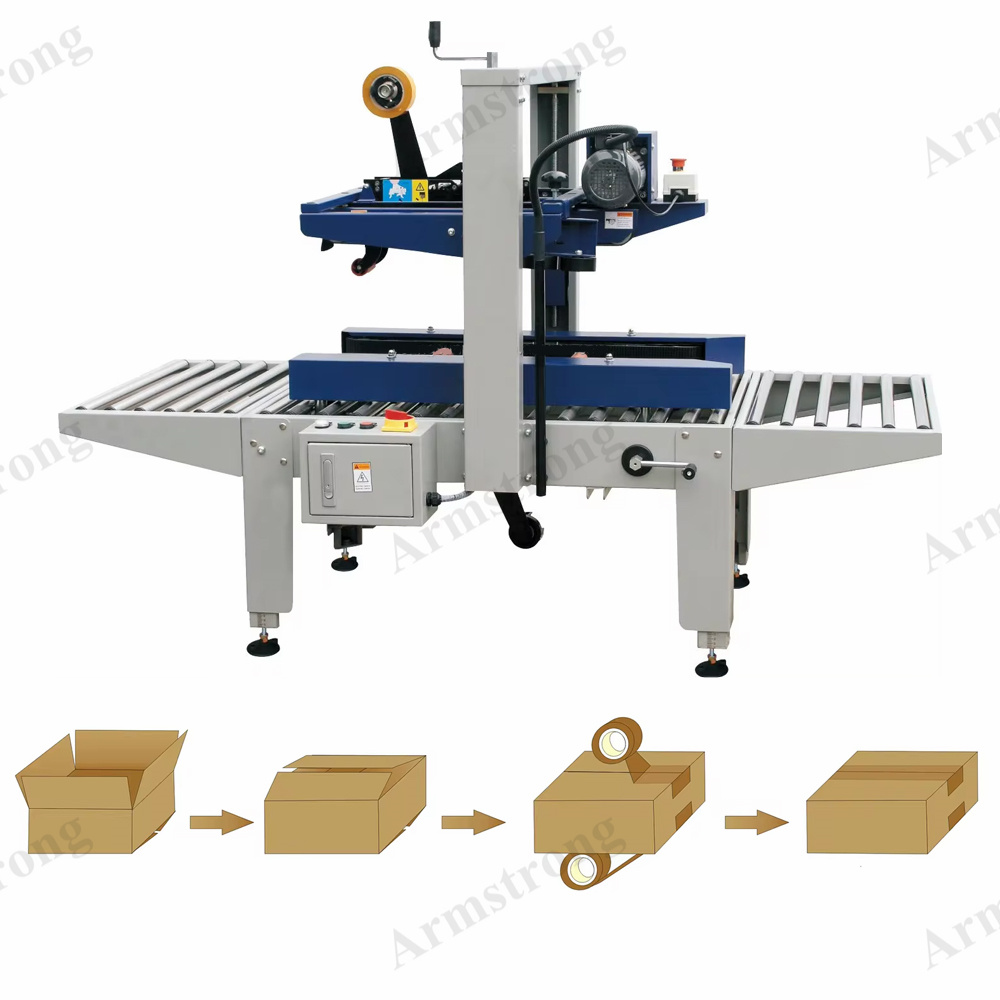

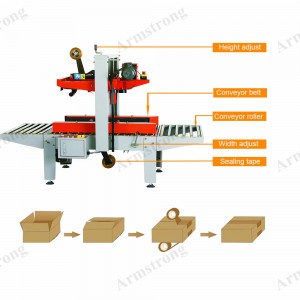

Case sealer

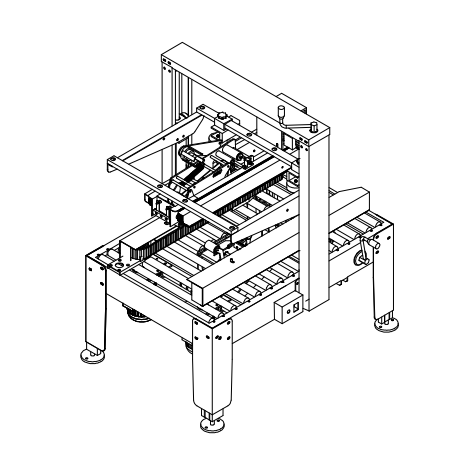

Machine overview

operational principle

The case sealer machine consists of a conveying system, two sealing mechanism, and a control system. The workflow is roughly as follows: Firstly, the cardboard boxes to be sealed are transported to the designated location through a conveyor belt.

Second, the sealing mechanism automatically positions and folds the top of the cardboard box.

Third, the tape mechanism accurately sticks the tape onto the seams of the cardboard box.

Forth, after completing the sealing, the cardboard box continues to move along the conveyor belt until it enters the next stage.

Advantage:

High efficiency: Compared to manual box sealing, the case sealer machine can complete the packaging of a large number of cardboard boxes in a short time, significantly improving production efficiency.

Quality assurance: Machine sealing is more standardized and unified, reducing the risk of unstable or damaged sealing caused by human factors.

Cost saving: In the long run, cardboard tape machines can reduce reliance on labor and lower labor costs.

Flexible adaptation: The machines have adjustment functions that can adapt to different sizes and shapes of cardboard boxes, with strong adaptability and flexibility.

|

Technical Specifications |

|

| Power |

220V, 50Hz, 600W |

| Overall dimensions (mm) |

L1090 * W890 * H (Table height plus 750) |

| Worktable height (mm) |

550-750(equipment foot adjustable) |

| Sealing speed |

19 m/min |

| Sealing size |

Length:150-∞; Width: 120-480mm; Height: 120-500mm |

| Sealing tape |

Kraft paper tape, BOPP tape |

| Weight |

100kg |

| Machine performance |

When changing the carton specification, the left and right, up and down need manual positioning adjustment, automatic timely transportation, up and down sealing at the same time. |

| Electrical configuration |

CPG Motor |

| Environmental requirement |

Humidity ≤ 98%, Temperature: 0-40 ℃ |

Video