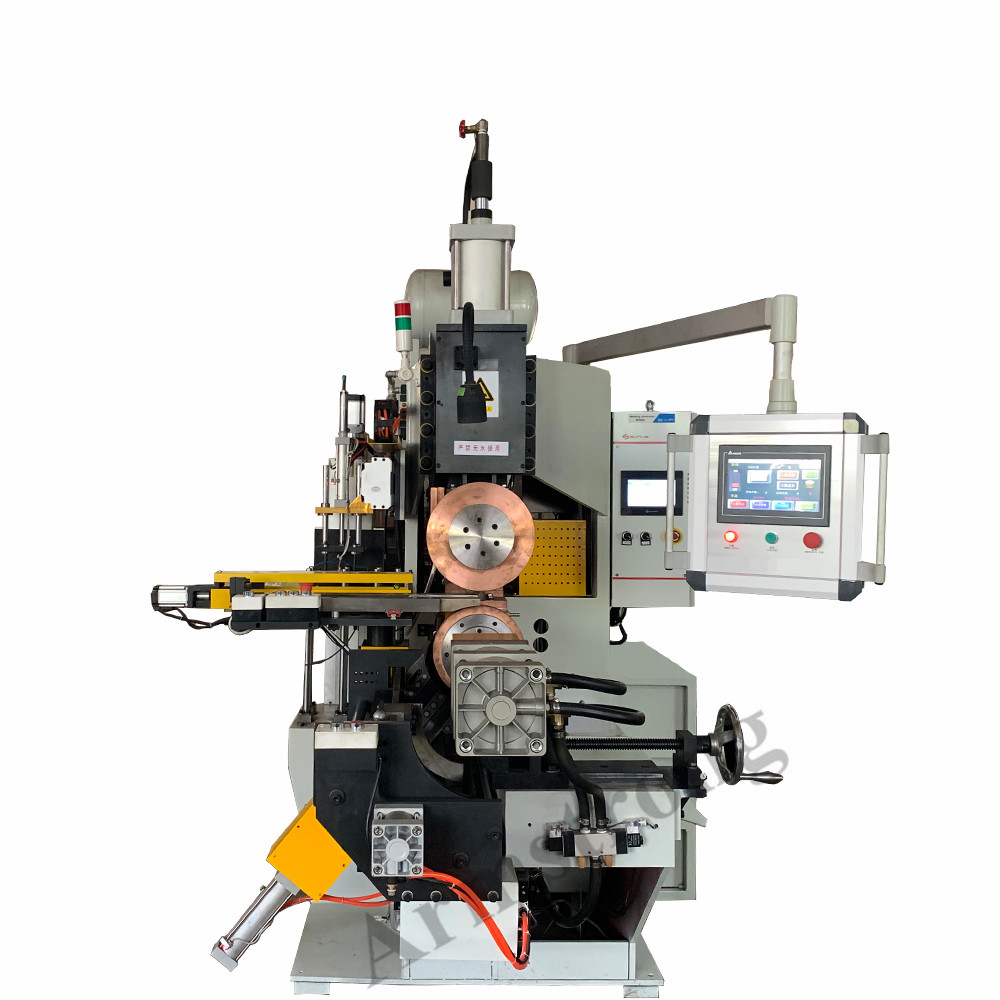

Roller Welding Machine A-BP400

Application:

Roller welding, also known as circumferential seam welding, is a method that uses a pair of roller electrodes to replace the cylindrical electrodes of spot welding, and the welded workpieces move between the rollers to produce a sealing weld with overlapping nuggets to weld the workpieces. AC pulse current or amplitude modulation current is generally used, and three (single) phase rectified, intermediate frequency and high frequency DC current can also be used. Roll welding is widely used for thin plate welding of sealed containers in oil drums, cans, radiators, aircraft and automobile fuel tanks, rockets and missiles. Generally, the welding thickness is within 3mm of single plate.

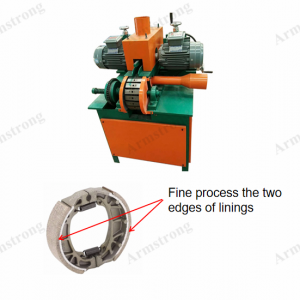

The brake shoe in automobile is mainly composed of a plate and a rib. We usually combine these two parts by welding process, and the roller welding machine effects at this time. This intermediate frequency roller welding machine for automobile brake shoe is an ideal special welding equipment designed and manufactured by our company for automobile brake production according to the welding technical requirements of brake shoes.

The equipment has a wide range of applications and is suitable for the welding of single reinforcement of automobile brake shoe. The touch screen digital input is used to control the operation settings, which is simple and convenient to operate.

The equipment accessories (panel material rack, conductive box, servo drive, clamping mold, pressure welding cylinder) are world-famous brand products. In addition, the high-precision planetary reducer can improve the positioning accuracy of the shoe.

It also adopts single chip microcomputer as the main control unit, which has the characteristics of simple circuit, high integration and intelligence, reduces the failure rate and is convenient for maintenance.

The communication and BCD code control function section is externally connected with industrial computer, PLC and other control equipment to realize remote control and automatic management, which improves work efficiency. 16 welding specifications can be stored for users to call the pre position.

The output frequency of the intermediate frequency controller is 1kHz, and the current regulation is fast and accurate, which can not be achieved by ordinary power frequency welding machines.