800L plow and rake mixing machine

1. Application:

RP868 800L Plow and Rake Mixing Machine is the latest mixing equipment designed with reference to ludige mixer in Germany. It is a high-tech product that fills the domestic gap and replaces imports. It can be widely used in the following different industrial fields:

1. Friction materials (especially for non asbestos materials)

It can mix and crush fibers, metals, additives, dry or liquid binders.

2. Organic or inorganic chemicals and natural substances

Phosphoric acid, sodium carbonate, acid carbonate and trace elements are used to produce fluid and soluble phosphoric acid fertilizer. The formation order is liquid, solid and made into pellet products.

3. Medicine

Dry mixing of base materials, wet treatment of binder and solvent, and pill making. All processes can be completed in one mixer. The products have good homogeneity and uniform size.

4. Cosmetics

It is used for mixing a small amount of oil and essential oil with talc powder. The mixture absolutely does not contain lumps.

5. Soaps and detergents

Manufacture all types of industrial cleaners. On the synergistic components (polyphosphate, sodium silicate, sodium phosphate, sodium carbonate, etc.), spray (anionic or non-ionic) WAS.

6. Dye, paint and spray lacquer

It can be applied to various pigments and diluents with different densities and particle sizes to manufacture and adjust paint products.

7. Chemical industry

Manufacture fire extinguishing powder with high fluidity, high density and good hydrophobicity.

8. Food industry

Solid or fluid fats, and slurry fillers can be mixed evenly. When dealing with brittle materials, the machine can not damage the materials, and can complete all procedures in one machine. Baking ingredients (sugar, salt, solid and fluid fat) can be used to make uniform and high fluidity special flour (baking powder, Cake Ingredients).

9. Ironmaking and glass industry

The ground iron ore, dry additives and water can be mixed to make pellets. It can also be used in the production of fireproof glass and optical glass.

10. Feed industry

The continuous mixer is especially suitable for the uniform mixing of various components in feed processing. With the help of adding fluid components, it can be made into pellets in the mixer and dried directly to produce pellet feed.

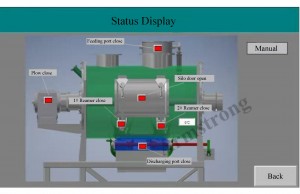

2. Working principles:

A plurality of plow shaped stirring shovels are designed on the middle horizontal axis of the circular barrel of the horizontal axis, and their rotation makes the materials move in the whole space of the barrel. The motion trajectories of the material particles crisscross and strike each other, and the motion trajectories change immediately. The particles collide against the inner wall of the agitator and the plowshare, and continue the whole mixing process. The turbulent vortex generated under the action of stirring can avoid the immovable zone of materials, so as to quickly obtain the mixture with accurate composition. Based on the principle of spin hammer, the mixture is uniform, and the brittle and heat sensitive materials can be protected at the same time.

A high-speed stirring reamer is designed on one side of the barrel to further improve the mixing efficiency and break the agglomerates in the materials, so as to ensure the complete mixing of powder, fluid and slurry additives. The stirring reamer can be opened and closed freely at any time, free control, not affected by the movement of the stirring shovel. The position of the stirring reamer is between the plow shaped agitator shovels, so the movement track of the plow is also consistent due to the movement of the stirring reamer.